Description

Vampire 3/4″ Jetting Nozzle – General Pipe Cleaning Solution

The Vampire 3/4″ jetting nozzle is designed for reliable and efficient pipe cleaning during routine maintenance operations. General cleaning nozzles play an essential role in keeping pipelines free from residue, grease, and light blockages. In this category, the Vampire 3/4″ model stands out for its versatility, offering a rear-jet configuration optimized for long-distance cleaning and the option to add a front jet when additional penetration is required.

Technical Features of the Vampire 3/4″ Nozzle

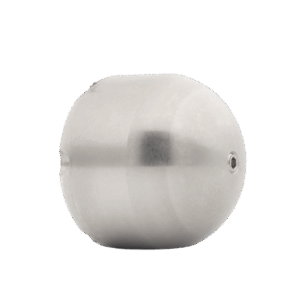

This nozzle is manufactured from stainless steel, ensuring durability and strong resistance to corrosion under professional use. It features a 3/4″ threaded connection that can be adapted to 1/2″ when needed, making it compatible with a wide range of high-pressure hoses. Its design allows effective cleaning of pipes with diameters from 8″ to 12″ when operating with the 3/4″ connection.

Cleaning Performance and Jet Configuration

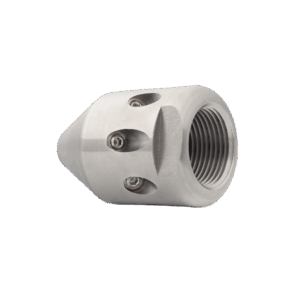

The Vampire 3/4″ jetting nozzle cleans pipelines using six rear jets angled at 35°. This configuration generates strong pulling force while directing water efficiently along the pipe walls. In addition, an optional front jet can be installed to help break through localized blockages and improve cleaning results. The nozzle operates with a minimum water flow of 16 GPM when using the 3/4″ thread, delivering stable and consistent performance.

Applications and Typical Uses

Professionals use this nozzle in municipal sanitation, industrial maintenance, and infrastructure cleaning tasks. It is especially suitable for general pipe cleaning, removal of grease buildup, soap residue, and light solid waste. Therefore, it is an effective solution for routine maintenance programs where reliability and controlled cleaning are essential.

Durability and Operational Benefits

The stainless steel construction extends service life and minimizes wear during continuous operation. Moreover, the rear-jet layout allows the nozzle to travel long distances inside pipelines with stable movement. Consequently, operators benefit from efficient cleaning, reduced maintenance requirements, and extended pipe lifespan.