Description

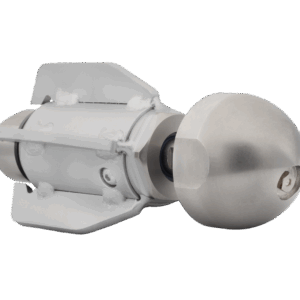

Tiger 3/8″ Jetting Nozzle – Compact Pipe Cleaning Solution

The Tiger 3/8″ jetting nozzle is engineered for efficient pipe cleaning and routine unclogging in small- to medium-diameter sewer and drainage systems. Its compact stainless steel construction and balanced rear-jet configuration provide reliable propulsion and effective debris removal in demanding field conditions.

Tiger 3/8″ Jetting Nozzle – Stainless Steel Construction

Manufactured from durable stainless steel, this jetting nozzle offers corrosion resistance and long service life under high-pressure operation. The integrated 3/8″ threaded connection ensures compatibility with standard professional hose assemblies.

Hydraulic Performance of the Tiger 3/8″ Jetting Nozzle

The body incorporates four rear M4 jets, designed to generate stable propulsion and consistent wall cleaning. Operating from 8 GPM, the hydraulic layout maintains steady pulling force while transporting loosened debris toward the outlet. As a result, the nozzle travels smoothly through pipes with diameters from 3″ to 6″.

Applications in 3″ to 6″ Sewer Lines

This configuration is widely used in municipal sanitation systems, building maintenance services, and light industrial cleaning operations. Its compact geometry allows extended travel inside pipelines, including bends and narrow sections where maneuverability is essential.

Durability and Operational Reliability

The reinforced stainless steel structure minimizes wear while maintaining hydraulic balance. Consequently, operators achieve efficient debris transport and controlled movement with reduced vibration. The simple yet effective design makes this configuration a dependable choice for daily pipe maintenance tasks.

Operational Stability of the Tiger 3/8″ Configuration

The balanced rear-jet configuration improves directional control during operation. Because the four M4 jets distribute hydraulic force evenly, the nozzle maintains consistent propulsion even when encountering partial obstructions. As a result, operators achieve smoother forward movement and more predictable debris transport.

In addition, the compact 3/8″ format reduces hose drag and improves maneuverability inside tight bends and service connections. Therefore, this configuration performs especially well in routine maintenance programs where reliability and ease of handling are essential.

In summary, this stainless steel configuration combines compact dimensions, four rear propulsion jets, and durable construction to deliver reliable and economical pipe cleaning performance.