Description

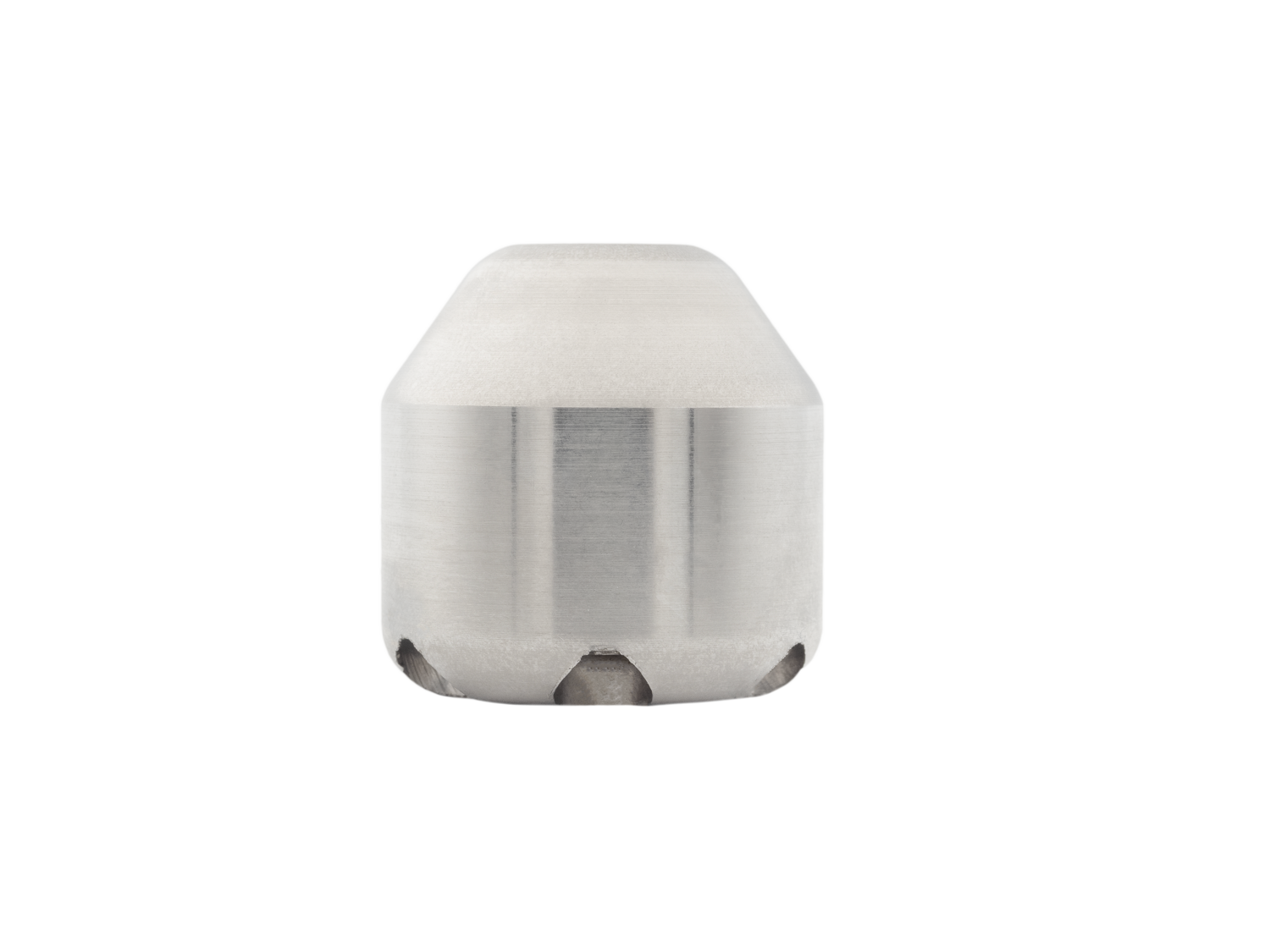

Tiger 1/4″ Jetting Nozzle – Compact Drag and Pipe Cleaning Solution

The Tiger 1/4″ jetting nozzle is engineered for powerful drag and pipe cleaning performance in small-diameter sewer and drainage systems. Its compact stainless steel body combines strong rear propulsion with a focused front drilling jet, allowing operators to break through compacted debris while maintaining steady forward movement inside tight pipe sections.

Stainless Steel Construction of the Tiger 1/4″ Jetting Nozzle

Manufactured from durable stainless steel, this jetting nozzle offers corrosion resistance and long service life under continuous high-pressure operation. The integrated 1/4″ threaded connection (optional 1/8″) ensures compatibility with lightweight professional hose systems.

Hydraulic Drag and Front Drilling Performance

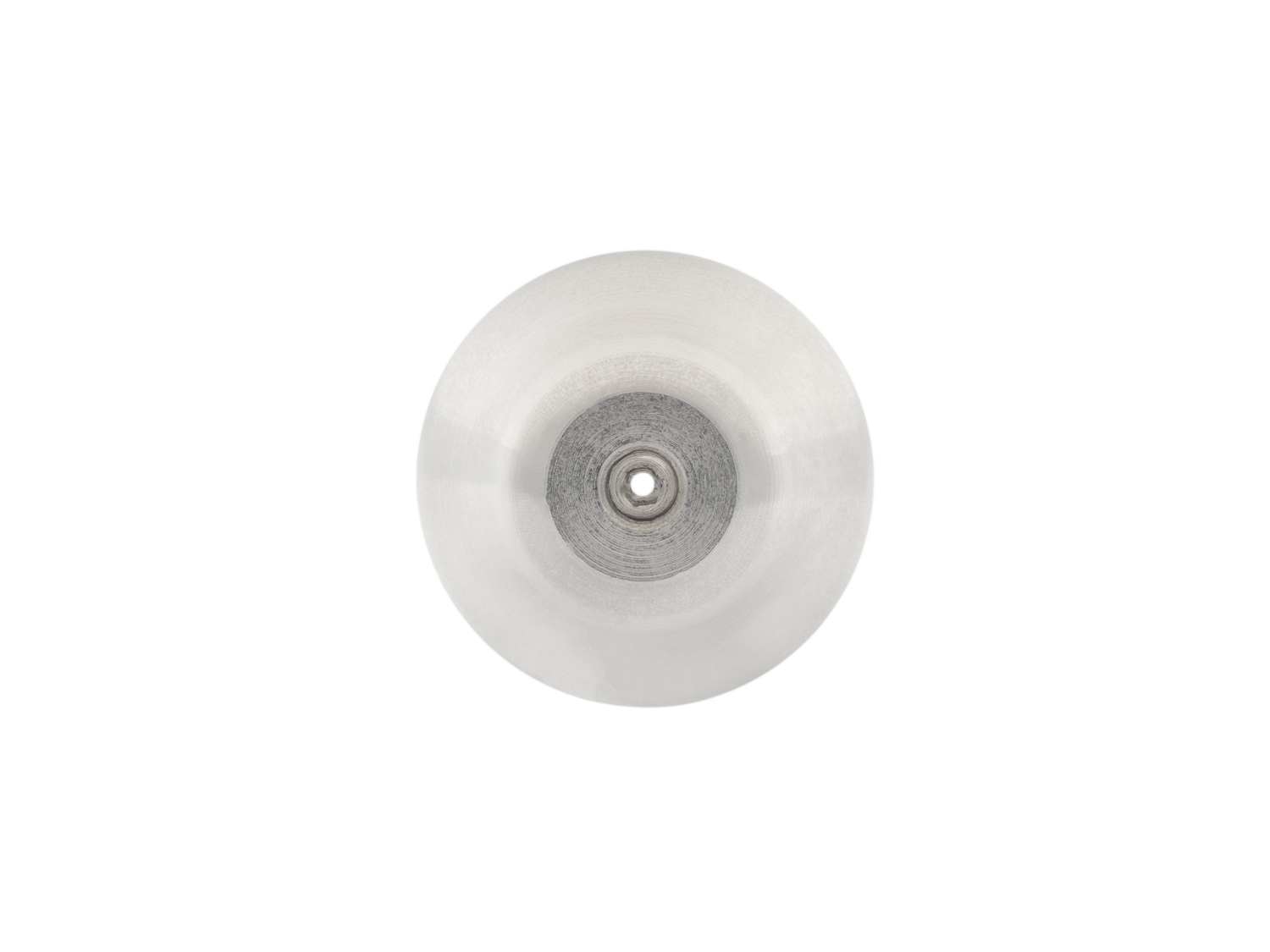

The body incorporates six ceramic rear M4 jets that generate strong propulsion and wall cleaning. At the same time, a powerful front jet drills into grease buildup and compacted obstructions. Operating from 10 GPM, the hydraulic configuration maintains consistent pulling force while transporting loosened debris toward the outlet.

Applications in 3″ to 6″ Sewer Lines

This configuration performs efficiently in pipes ranging from 3″ to 6″. Its compact geometry allows smooth navigation through elbows and restricted sections where larger tools struggle. As a result, operators achieve effective cleaning in residential, municipal, and light industrial maintenance work.

Operational Reliability and Cleaning Efficiency

The balanced jet distribution improves directional control and reduces vibration during operation. Because the rear ceramic inserts resist wear, the nozzle maintains stable performance even in abrasive environments. This makes it a dependable solution for routine maintenance and corrective unclogging tasks.

The hydraulic balance between the front drilling jet and the six rear ceramic jets ensures controlled penetration without excessive recoil. This improves operator stability during long cleaning runs and reduces unnecessary hose stress. In addition, the ceramic jet inserts resist abrasion caused by sand and mineral particles, maintaining consistent spray angles and cleaning force over time. As a result, maintenance intervals are extended and overall operational costs are reduced.

In summary, this compact stainless steel configuration combines aggressive front drilling, strong rear propulsion, and durable construction to deliver reliable pipe cleaning performance in confined sewer systems.