Description

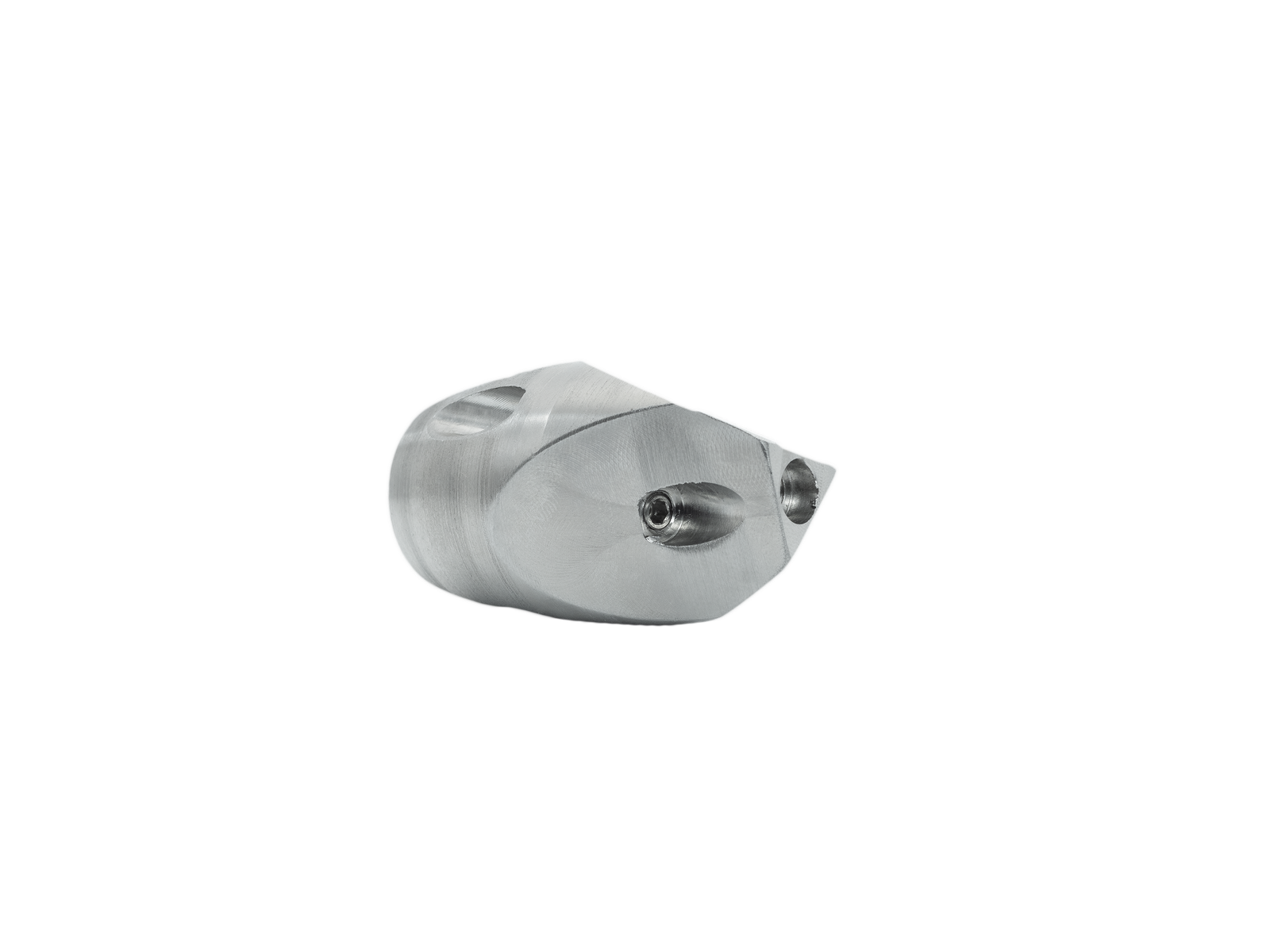

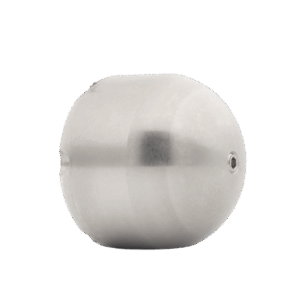

Breaker 3/8″ Jetting Nozzle – Deep Unblocking Solution

The Breaker 3/8″ jetting nozzle is engineered for aggressive pipe penetration and deep unblocking in sewer and drainage systems. It combines cutting impact and hydraulic propulsion to remove root masses, frozen systems, grease buildup, and compacted debris inside medium-diameter pipelines.

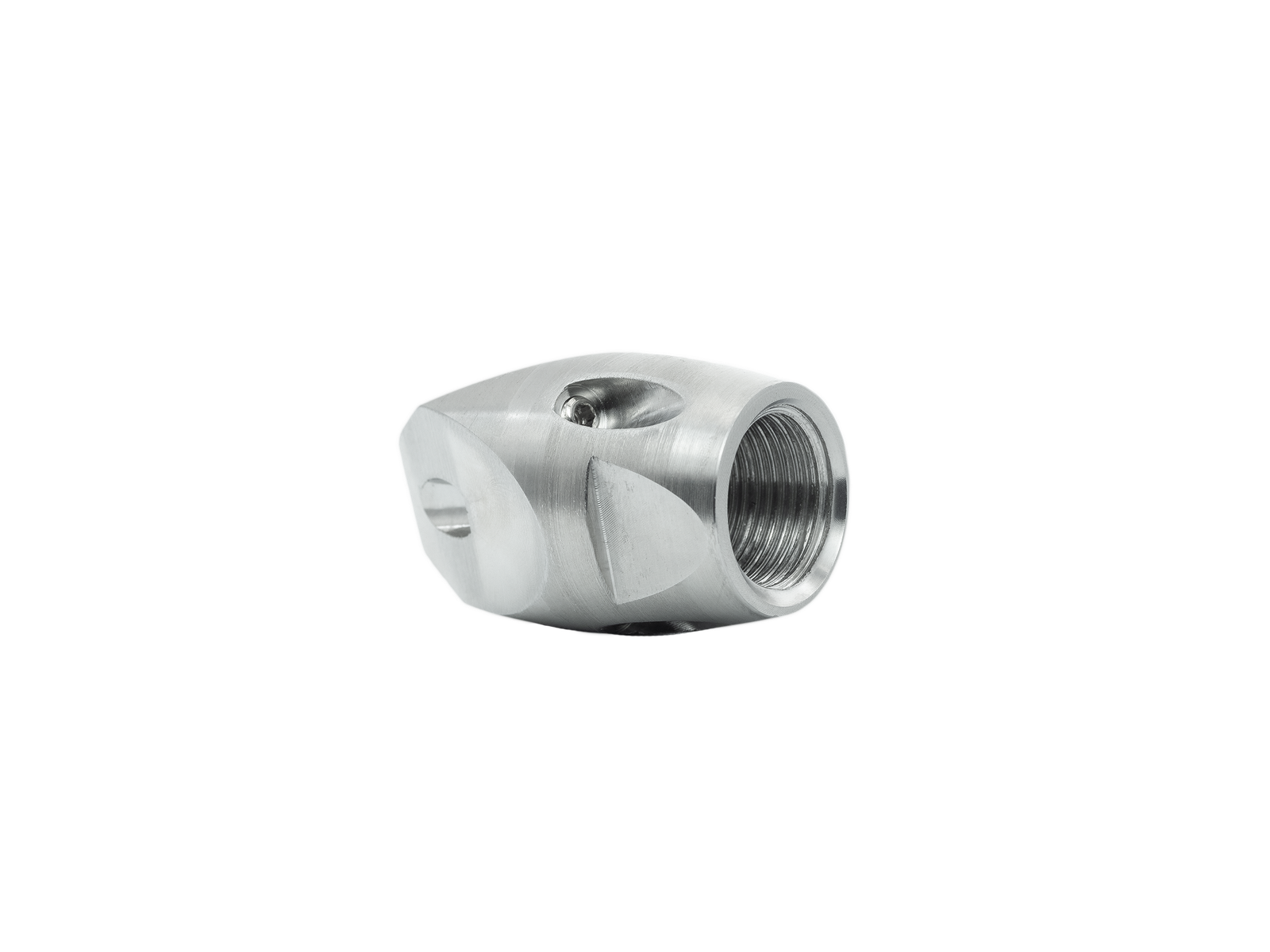

Stainless Steel Construction and 3/8″ Thread Compatibility

Manufactured from durable stainless steel, this jetting nozzle offers corrosion resistance and structural strength under high-pressure conditions. The integrated 3/8″ threaded connection ensures compatibility with professional hose systems used in municipal and industrial maintenance.

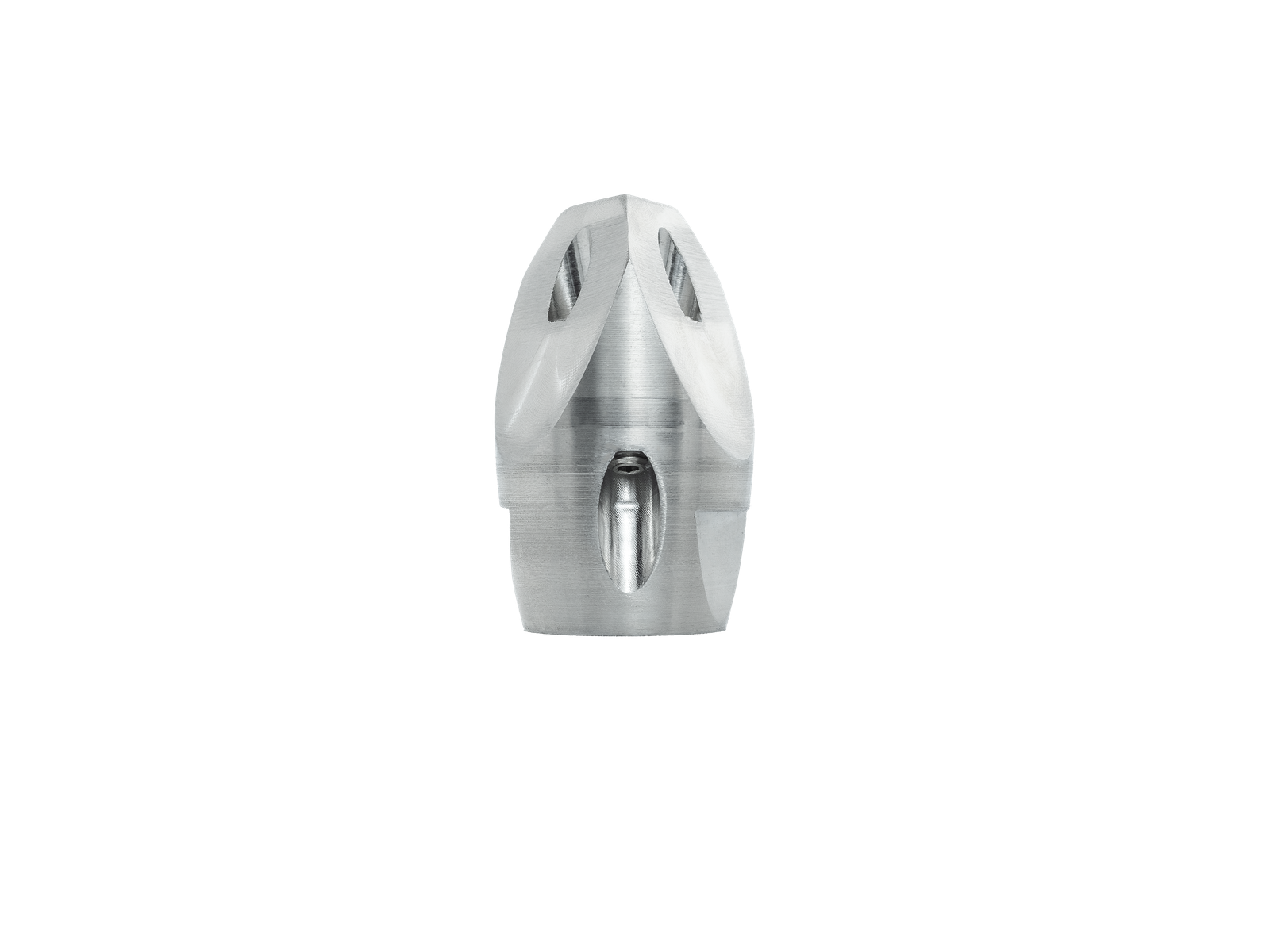

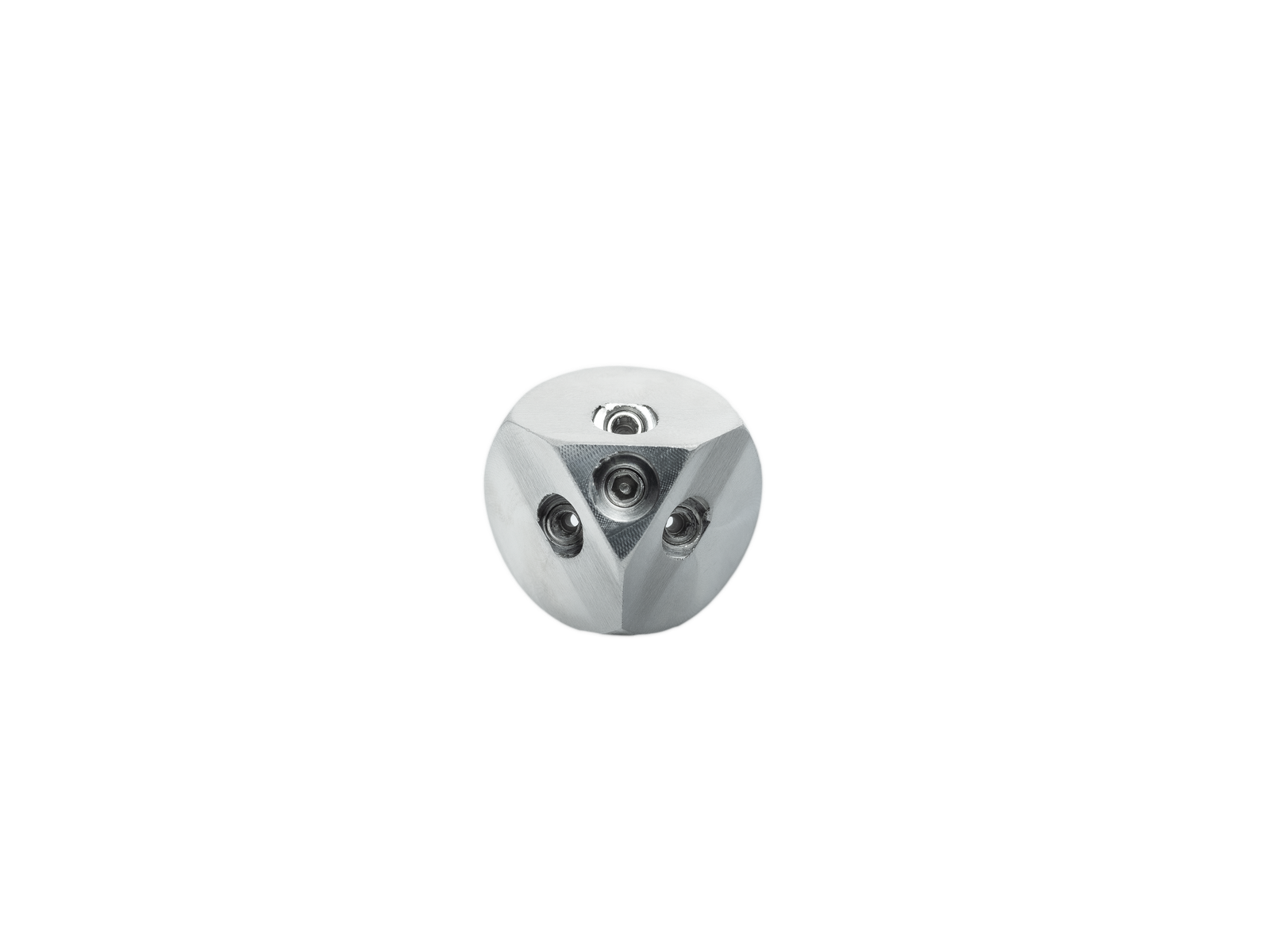

Cutting and Propulsion Jet Configuration

This configuration incorporates three front M4 jets for penetration and three rear M6 jets for propulsion and debris extraction. Operating from 10 GPM, the hydraulic layout delivers forward impact while maintaining stable pulling force. As a result, dense obstructions are fractured and transported efficiently toward the outlet.

Applications of the Breaker 3/8″ Jetting Nozzle in 3″ to 6″ Pipes

Designed for pipelines ranging from 3″ to 6″, this cutting configuration performs effectively in municipal sanitation systems, industrial drainage networks, and infrastructure maintenance programs. Its angular geometry improves penetration into hardened buildup while supporting controlled movement inside bends and junctions.

Operational Stability and Long-Term Durability

The reinforced body reduces vibration while preserving hydraulic balance. Consequently, operators achieve deeper cleaning with fewer passes and improved debris transport efficiency. The stainless steel construction minimizes wear, extends service life, and maintains consistent performance in demanding environments.

Hydraulic Impact of the Breaker 3/8″ Jetting Configuration

The hydraulic configuration of this cutting nozzle is designed to maintain directional control while delivering concentrated impact force at the front. The three forward jets create a focused penetration effect, while the rear propulsion jets stabilize movement inside the pipeline. This balance prevents unnecessary rebound and improves contact with hardened obstructions. As a result, operators gain better control during aggressive unblocking tasks, especially in partially collapsed or irregular pipe sections.

In addition, the compact 3/8″ format allows improved maneuverability in confined spaces where larger bodies may struggle. This makes the configuration particularly suitable for service vehicles equipped with lighter hose assemblies while still delivering professional-grade cutting performance.

In summary, this stainless steel cutting configuration combines front impact jets and rear propulsion force to deliver reliable deep unblocking performance in professional sewer cleaning applications.