Description

Breaker 1/4″ Jetting Nozzle – Deep Unblocking and Cutting Solution

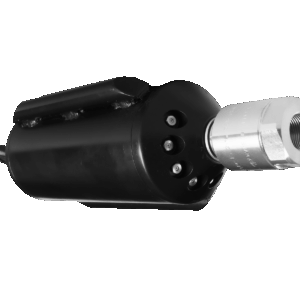

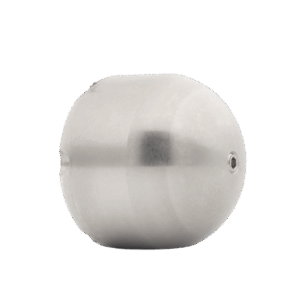

The Breaker 1/4″ jetting nozzle delivers aggressive penetration in small- to medium-diameter sewer systems. It breaks through dense blockages such as roots, frozen buildup, grease, and compacted debris. Its compact stainless steel body combines front cutting power with strong rear propulsion for controlled and effective cleaning.

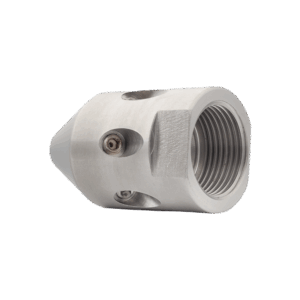

Breaker 1/4″ Jetting Nozzle – Stainless Steel Construction

We manufacture this jetting tool from high-grade stainless steel to ensure corrosion resistance and long service life. The integrated 1/4″ threaded connection fits lightweight professional hose systems. The compact design allows operators to work efficiently in pipes ranging from 3″ to 6″.

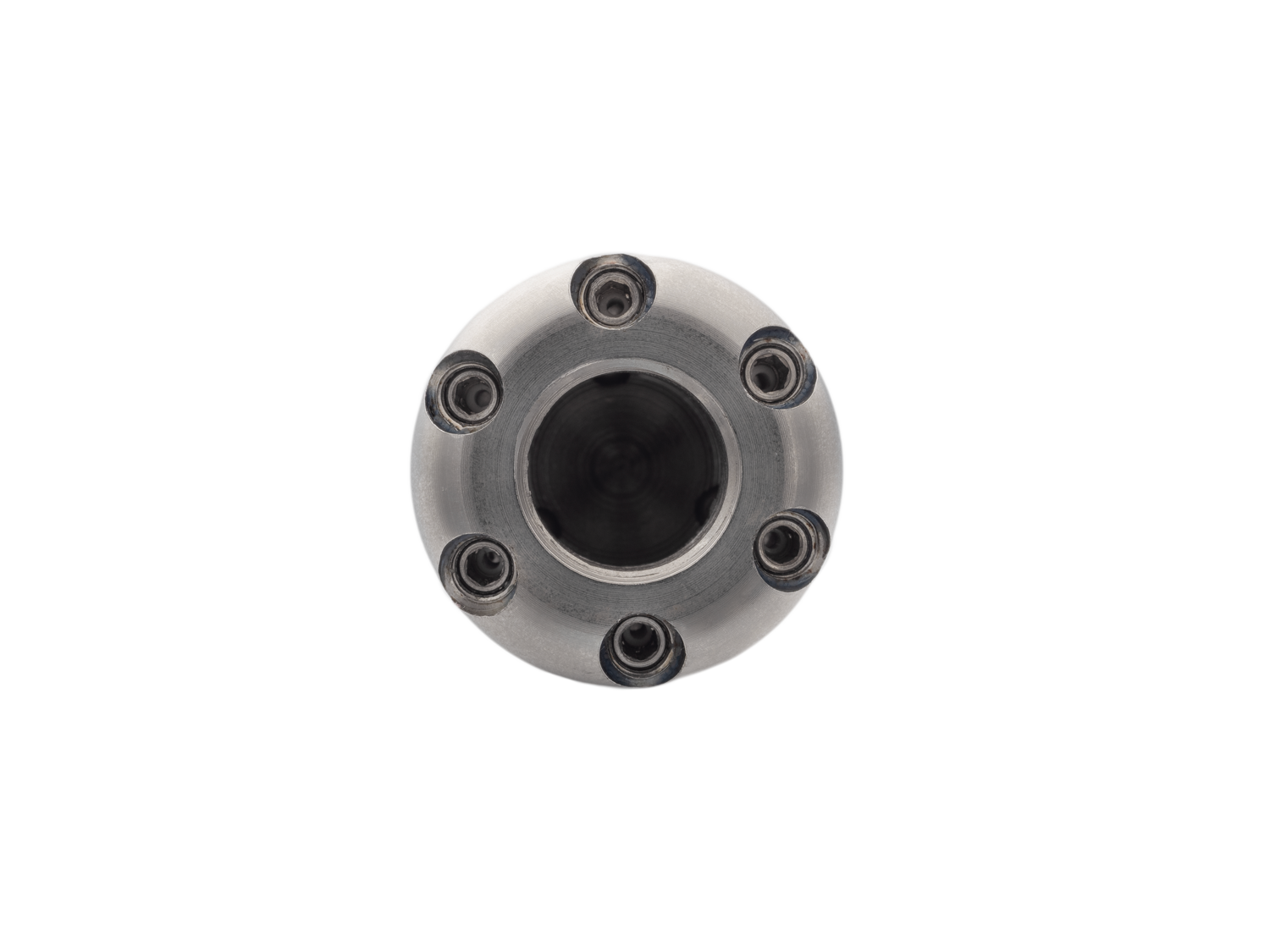

Hydraulic Cutting Performance and Jet Configuration

The head features three front M4 jets that concentrate hydraulic force for direct penetration. In addition, six rear M4 jets generate propulsion and transport debris backward. The nozzle operates from approximately 10 GPM, maintaining strong cutting action and steady forward movement.

The front jets fracture hardened obstructions. Meanwhile, the rear jets pull the tool forward and evacuate loosened material. This balanced configuration prevents debris from being pushed deeper into the pipeline and reduces the number of cleaning passes required.

Applications of the Breaker 1/4″ Jetting Nozzle

Professionals use this configuration in municipal sanitation, industrial drainage, and infrastructure maintenance. It performs especially well in emergency situations where pipe flow is severely restricted by roots, solid waste, or ice formation.

Durability and Operational Reliability

The reinforced body withstands abrasive environments and repeated high-pressure cycles. The balanced hydraulic layout controls vibration and improves directional stability. As a result, operators achieve predictable performance and consistent debris removal.

For technical reference about high-pressure cleaning principles, you can review the general concept of a nozzle and its hydraulic behavior in industrial applications. Understanding flow dynamics helps operators select the correct configuration for each pipe diameter and obstruction type.

Because of its compact size and aggressive jet layout, this configuration also performs efficiently during preventive maintenance programs, where consistent hydraulic impact prevents recurring buildup and reduces emergency interventions.

In summary, this compact cutting configuration provides strong penetration, controlled propulsion, and reliable long-term performance in demanding pipe unblocking operations.