Description

Breaker 1/2″ Jetting Nozzle – Deep Unblocking and Cutting Solution

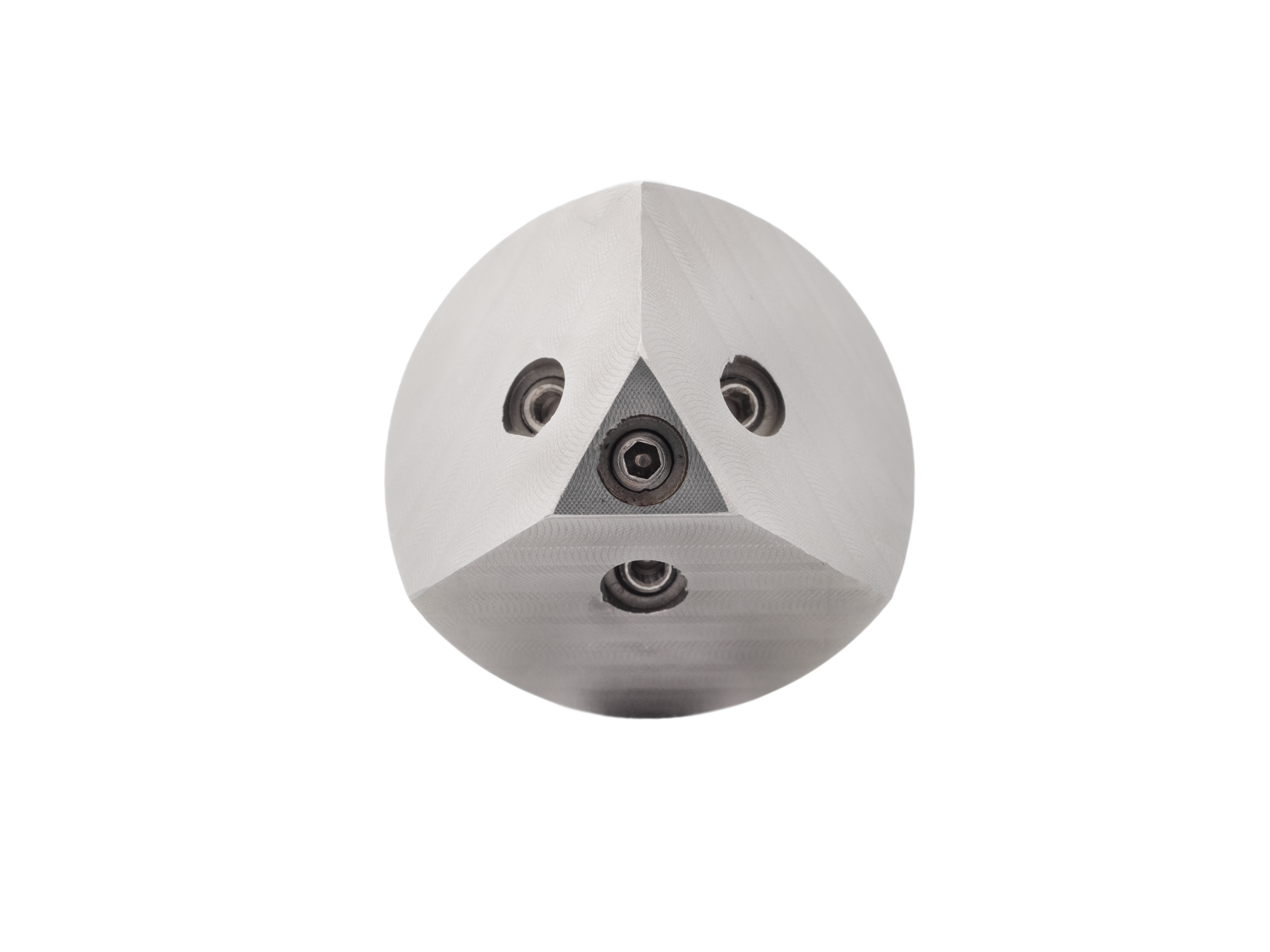

The Breaker 1/2″ jetting nozzle is designed for aggressive pipe unclogging when standard nozzles cannot penetrate compacted obstructions. Deep unblocking nozzles are essential for restoring flow in heavily blocked pipelines, and this model stands out thanks to its angular, cutting profile and high-impact jet configuration.

Technical Features

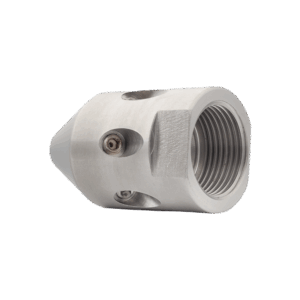

Manufactured from stainless steel, this nozzle offers excellent durability and corrosion resistance in demanding cleaning environments. It features a 1/2″ threaded connection, ensuring compatibility with professional high-pressure hoses. Its geometry allows effective operation in pipes with diameters ranging from 3″ to 8″.

Efficiency in Deep Unblocking Operations

This nozzle combines three front M4 jets with three rear M6 jets to deliver both cutting penetration and strong pulling force. The front jets attack compacted debris, roots, and frozen material directly, while the rear jets help evacuate loosened waste. In addition, it operates with a minimum water flow of 10 GPM, ensuring controlled and efficient performance in difficult conditions.

Applications and Typical Uses

Professionals commonly use the Breaker 1/2″ jetting nozzle in municipal sanitation, industrial pipe cleaning, and infrastructure maintenance. It is especially effective for cutting roots, breaking solid waste, and reopening frozen or severely obstructed service lines. Its aggressive profile allows operators to tackle tough blockages with precision and confidence.

Durability and Operational Benefits

The stainless steel construction extends service life and minimizes wear during continuous professional use. Moreover, the optimized jet layout reduces cleaning time and improves overall efficiency. As a result, operators benefit from reliable unblocking performance, reduced downtime, and longer pipe lifespan.

Conclusion

In summary, the Breaker 1/2″ jetting nozzle delivers powerful cutting and unblocking performance in compact pipe systems. Its combination of front cutting jets, rear pulling jets, and robust construction makes it a dependable solution for demanding professional pipe cleaning operations.