Description

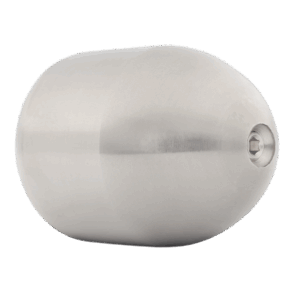

Alien 1/4″ Jetting Nozzle – Compact Rotating Unclogging Solution

The Alien 1/4″ jetting nozzle is designed for efficient unclogging and precision pipe cleaning in small- to medium-diameter sewer and drainage systems. Thanks to its compact dimensions and rotating front jet, this configuration delivers controlled penetration and reliable debris removal in tight and hard-to-reach pipelines.

Alien 1/4″ Jetting Nozzle – Functionality and Applications

Operating from a minimum flow of 8 gallons per minute (GPM), this jetting nozzle generates stable hydraulic propulsion while maintaining effective cutting action at the pipe front. Its compact size of 0.9″ x 1.6″ and lightweight construction of 0.3 lbs allow smooth navigation through bends, junctions, and narrow service connections.

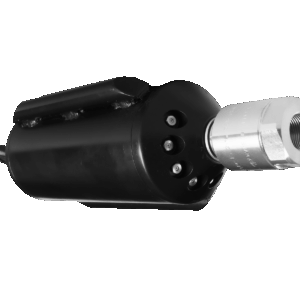

This configuration is commonly used in residential drainage systems, building maintenance, and light industrial cleaning operations where precise control and maneuverability are essential.

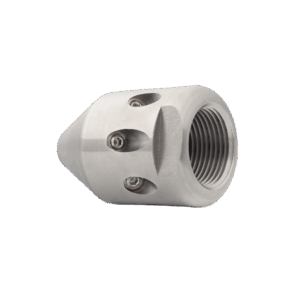

Rotating Jet Technology for Targeted Penetration

A key feature of this configuration is the rotating front jet supported by an internal bearing system. As water pressure increases, the jet rotates and drills into compacted grease, soap buildup, and fibrous obstructions. At the same time, angled rear jets provide propulsion and debris transport toward the outlet.

This combined action improves unclogging efficiency and reduces the number of passes required to restore full pipe flow.

Durability and Stainless Steel Construction

Manufactured from high-quality stainless steel, this tool resists corrosion and abrasion in demanding operating environments. The robust body construction ensures long service life even under frequent professional use. As a result, maintenance requirements remain low while performance stays consistent over time.

Operational Control and Cleaning Precision

Because of its balanced hydraulic design, the nozzle maintains directional stability during operation. This reduces hose vibration and improves operator control, especially in partially obstructed lines. Consequently, technicians achieve predictable cleaning results with minimal effort.

In summary, this compact rotating configuration combines durability, controlled cutting action, and efficient propulsion to deliver reliable unclogging performance in confined pipeline systems.