Description

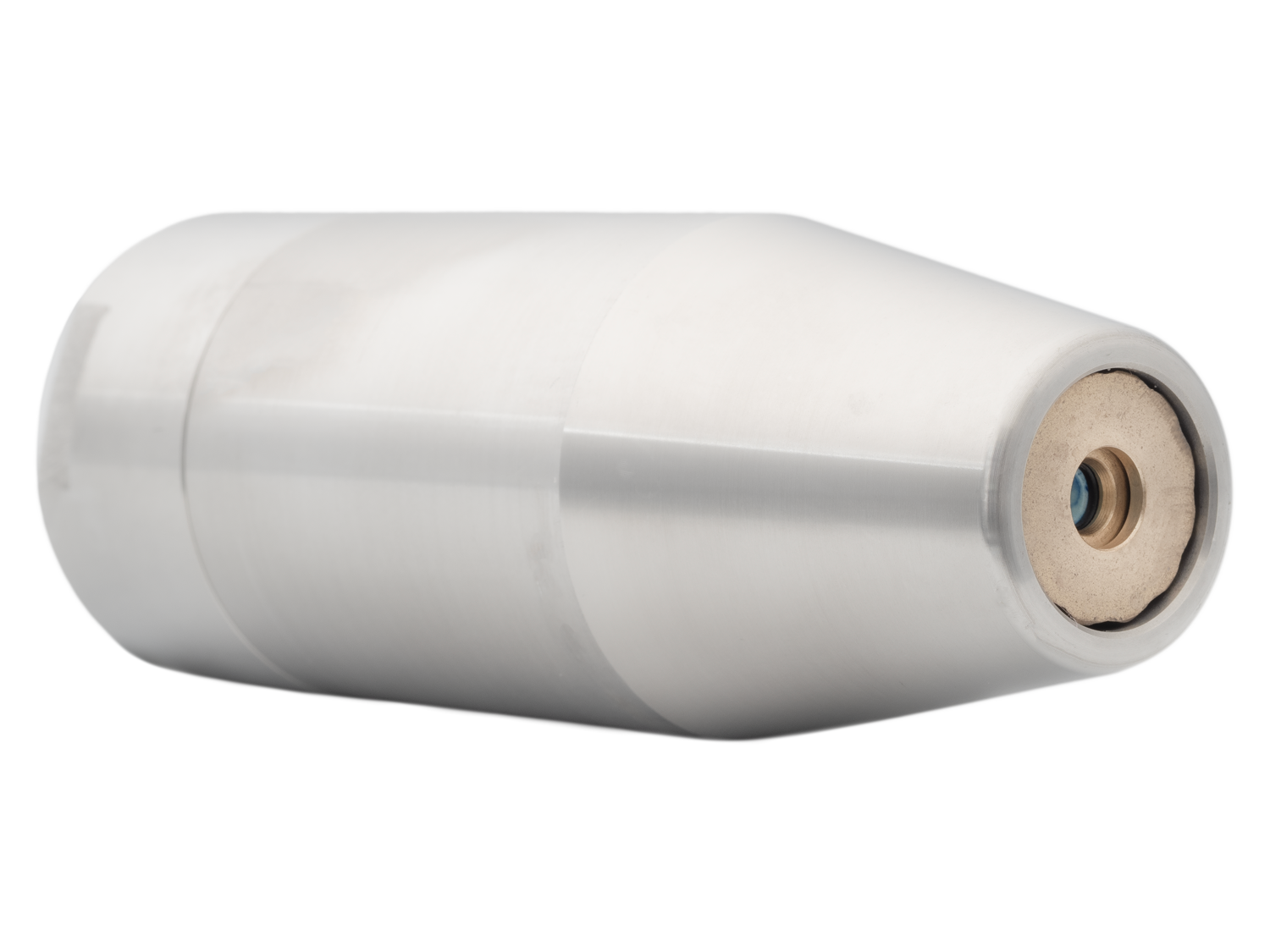

Alien 1/2″ Turbo Reduced to 3/8″ Jetting Nozzle – High-Impact Unclogging Solution

The Alien 1/2″ Turbo Reduced to 3/8″ jetting nozzle is engineered for aggressive pipe cleaning in medium and large diameter sewer systems. This reduced configuration connects to 3/8″ hose systems through a precision thread adapter while maintaining the hydraulic power and rotational cutting performance of the original 1/2″ turbo body.

Alien 1/2″ Turbo Reduced to 3/8″ Configuration

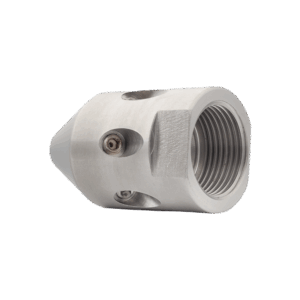

Manufactured from durable stainless steel, this jetting nozzle ensures corrosion resistance and structural strength under high-pressure conditions. The integrated reduction system adapts the original 1/2″ threaded body to a 3/8″ outlet, improving flexibility without compromising performance.

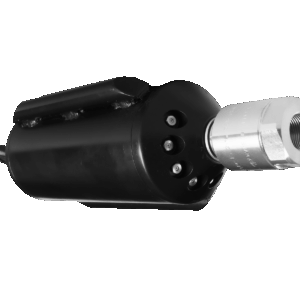

Turbo Jetting Nozzle Rotation and Rear M6 Jets

The head incorporates three rear M6 jets angled at 7º, generating strong propulsion and wall cleaning. Operating from 10 GPM, the hydraulic flow activates the internal bearing-supported rotating front jet. As a result, the nozzle drills into compacted debris and fibrous obstructions while maintaining steady forward movement.

Applications of the 1/2″ Turbo Reduced to 3/8″ Nozzle

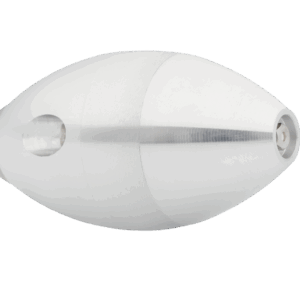

This turbo configuration performs efficiently in pipes ranging from 4″ to 18″. It is widely used in municipal sanitation systems, industrial drainage networks, and infrastructure maintenance programs. In addition, its tapered geometry improves navigation through bends and irregular pipe sections.

Durability and Reduced Maintenance for Turbo Cleaning

The robust stainless steel body and internal bearing mechanism ensure long service life even in abrasive environments. Because of its balanced hydraulic design, vibration remains controlled while maintaining effective debris transport toward the outlet.

- Original nozzle size: 1/2″

- Threaded connection: 3/8″

- Reduction method: 3/8″ thread adapter included

- Compatible with: 3/8″ fittings

Hydraulic Stability in the Reduced 3/8″ Turbo System

The balanced hydraulic distribution between the rotating front jet and the rear propulsion jets improves directional stability during operation. Consequently, operators experience smoother forward movement and reduced hose vibration in long pipeline sections. This stability enhances cleaning precision and ensures consistent debris transport throughout the unclogging process.

In summary, this turbo reduced configuration combines rotational cutting action and balanced propulsion to deliver powerful unclogging performance in demanding sewer applications.