Description

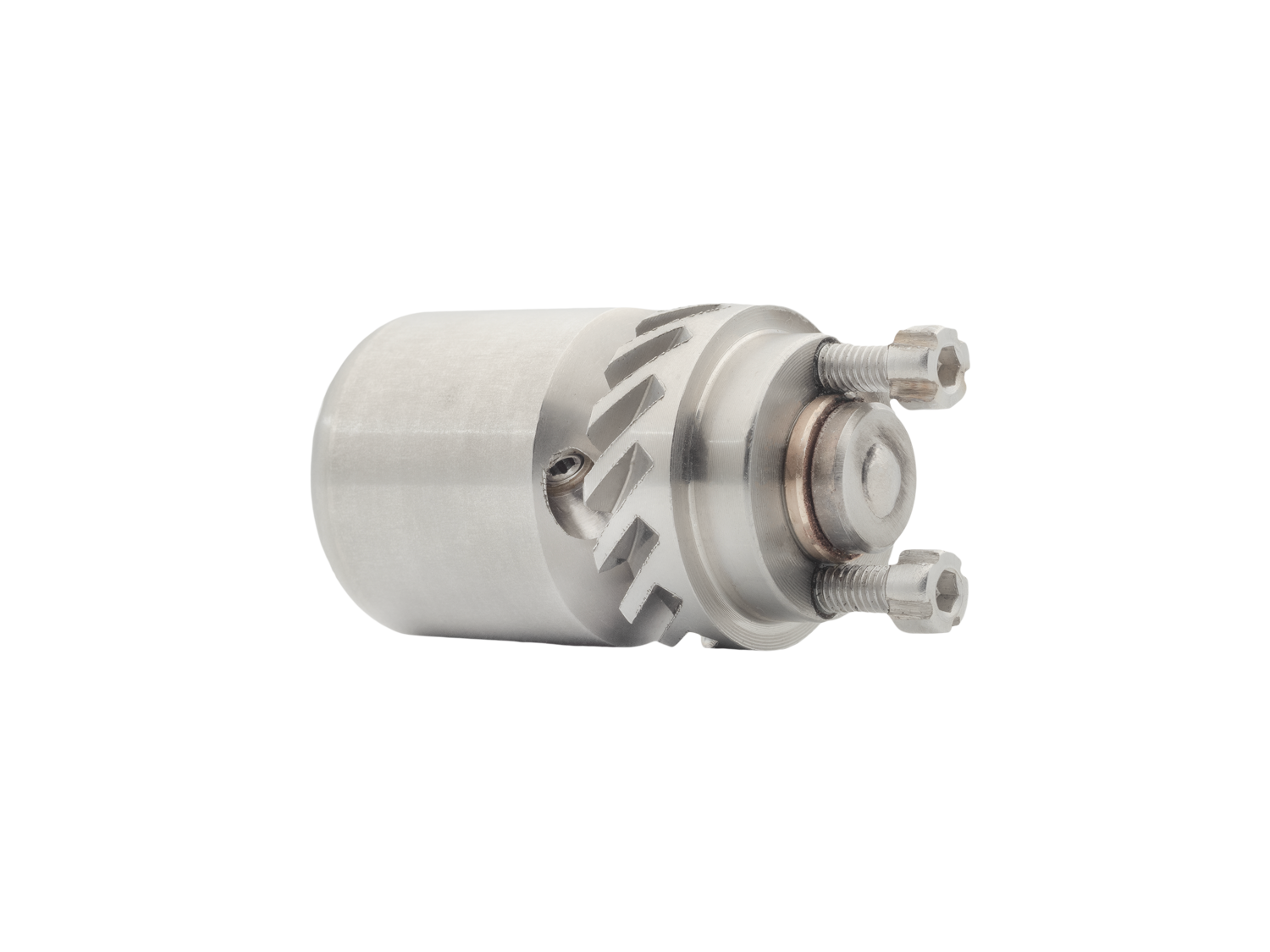

Rotating Wipe Catcher 1/4″ Jetting Nozzle – Textile and Rag Removal Solution

The Rotating Wipe Catcher 1/4″ jetting nozzle is specifically engineered to remove rags, wipes, and textile debris from small-diameter sewer and drainage systems. By combining hydraulic propulsion with a rotating turbine mechanism, it efficiently hooks and extracts fibrous obstructions that standard flushing tools cannot remove.

Stainless Steel Construction and 1/4″ Thread Compatibility

Manufactured from durable stainless steel, this jetting nozzle provides corrosion resistance and long service life under high-pressure operation. The integrated 1/4″ threaded connection ensures compatibility with lightweight professional hose systems used in residential and municipal maintenance work. It performs efficiently in pipes ranging from 2″ to 6″.

Rotating Turbine Mechanism and Rear Jet Propulsion

The internal rotating turbine activates under hydraulic flow starting at approximately 10 GPM. While six rear M4 jets angled at 7º generate forward propulsion, the turbine rotates and hooks textile debris during backward retrieval. As a result, operators can extract wipes and rags instead of pushing them deeper into the pipeline.

Rotating Wipe Catcher 1/4″ Jetting Nozzle Performance

Unlike conventional flushing tools that only disperse soft obstructions, this rotating configuration captures and pulls fibrous material toward the access point. Consequently, cleaning cycles become faster and more controlled, especially in systems affected by wet wipes, cloth fragments, or accumulated sanitary products.

Applications in 2″ to 6″ Sewer Lines

This compact configuration is widely used in municipal sanitation, facility maintenance, and industrial drainage services. Because the turbine works in combination with balanced hydraulic propulsion, the tool maintains directional stability while navigating bends and junctions.

During operation, the rotating turbine of the Rotating Wipe Catcher 1/4″ nozzle allows controlled engagement with textile debris while maintaining stable backward extraction. This operating principle reduces the risk of pushing rags deeper into the pipe and improves removal efficiency in confined or partially collapsed sections.

In summary, this stainless steel rotating textile-removal configuration delivers controlled propulsion, effective rag extraction, and long-term durability in demanding pipe cleaning environments.