Description

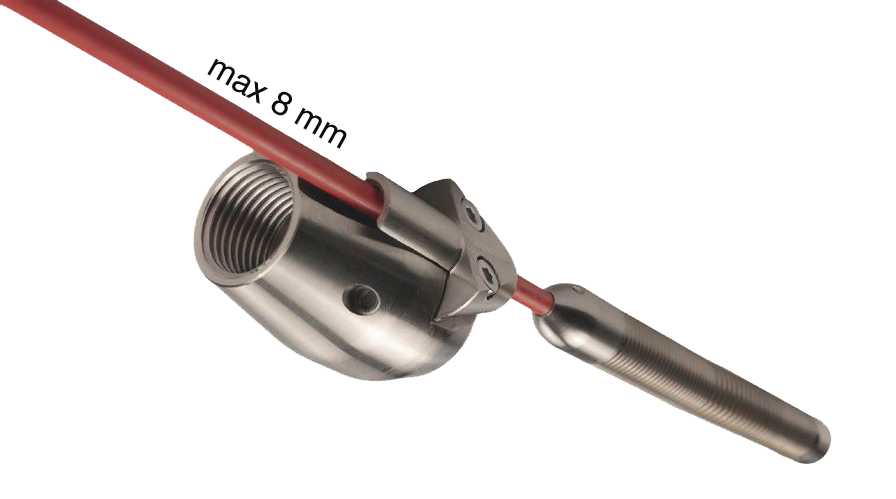

Camera Nozzle 1/4″ Jetting Nozzle – Inspection and Camera Guidance Solution

The Camera Nozzle 1/4″ jetting nozzle is specifically designed to assist manual pipe inspection by pushing and stabilizing the inspection camera head inside sewer and drainage systems. Unlike standard cleaning tools, this configuration focuses on controlled propulsion and precision guidance, allowing technicians to perform detailed visual evaluations in pipes ranging from 3″ to 8″.

Camera Nozzle 1/4″ Jetting Nozzle – Stainless Steel Construction

Manufactured from durable stainless steel, this jetting nozzle offers corrosion resistance and long service life under professional use. The integrated 1/4″ threaded connection ensures compatibility with standard high-pressure hose systems commonly used in inspection operations.

Hydraulic Configuration for Camera Maneuverability

The body incorporates three rear M6 jets that generate stable propulsion without excessive turbulence. Operating from approximately 10 GPM, the hydraulic layout maintains controlled forward movement, allowing the nozzle to slide along the fiber optic cable and reach the camera head smoothly. As a result, technicians gain improved directional control and better inspection stability.

Applications in Pipe Inspection Operations

This configuration is widely used in municipal sanitation services, industrial infrastructure evaluation, and preventive maintenance programs. It supports detailed internal inspection by helping operators guide the camera through bends, junctions, and partially obstructed sections. Therefore, it improves workflow efficiency and reduces manual force during long inspection runs.

Operational Stability and Precision Control

Because the rear jets distribute hydraulic force evenly, the Camera Nozzle 1/4″ nozzle maintains consistent propulsion while minimizing vibration. Consequently, image quality improves and camera positioning becomes more predictable. This balance between propulsion and stability makes it a reliable inspection accessory for confined and complex pipeline networks.

In addition, its compact 1/4″ format reduces overall system weight and improves handling during inspection procedures in residential and commercial environments. This practical balance between propulsion and precision makes it especially suitable for routine diagnostic operations and preventive maintenance programs.

In summary, this stainless steel inspection configuration combines controlled hydraulic propulsion, durable construction, and optimized camera guidance to deliver accurate and efficient visual pipe evaluation.