Description

Grades 30º Three Jets jetting nozzle – General Pipe Cleaning Solution

The Grades 30º Three Jets jetting nozzle is designed for routine pipe cleaning and maintenance in sewer and drain systems. This professional jetting nozzle combines three rear jets angled at 30 degrees with a frontal jet to ensure strong wall coverage and effective forward penetration.

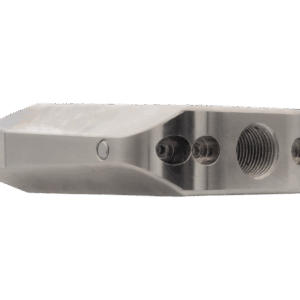

Grades 30º Three Jets jetting nozzle – Stainless Steel Construction

Manufactured from stainless steel, this cleaning tool offers excellent durability and corrosion resistance in demanding environments. It features a 1/2″ threaded connection compatible with standard high-pressure hoses. Its compact body allows efficient operation in pipes ranging from approximately 4” to 8” (100–200 mm).

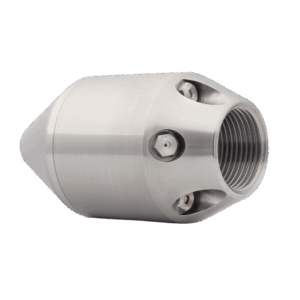

Grades 30º Three Jets Jetting Nozzle – Rear Jet Angle and Front Penetration

The head incorporates three rear M6 jets angled at 30º, designed to maximize wall impact and debris removal. The additional front jet improves penetration through light obstructions and compacted buildup. The system operates efficiently from 10 GPM (40 l/min), delivering stable and uniform cleaning performance.

Applications in Sewer and Drain Maintenance

This three-jet configuration is ideal for municipal sanitation, industrial maintenance, and infrastructure cleaning. It performs effectively in removing soap deposits, light solids, sediment, and routine buildup. The 30-degree jet geometry increases surface contact, helping maintain pipe walls in optimal condition.

Operational Advantages

Balanced water distribution reduces vibration and supports consistent propulsion along the pipeline. The stainless steel body ensures long service life and predictable maintenance intervals, making this solution reliable for everyday professional jetting operations.

30º Rear Jet Angle and Hydraulic Performance and Cleaning Coverage

The 30º rear jet orientation increases wall contact and improves circumferential cleaning coverage compared to flatter jet angles. This makes the nozzle particularly effective for preventive maintenance programs where consistent surface cleaning is required. Because the water impact is distributed evenly, operators achieve reliable debris transport while maintaining steady forward movement through straight runs and gradual bends.

Compatibility and Field Flexibility

Designed for compatibility with common high-pressure jetting units, this nozzle integrates easily into existing cleaning fleets. Its balanced geometry allows smooth hose handling and predictable control, reducing operator fatigue during extended work sessions. Whether used for scheduled maintenance or corrective cleaning, it delivers dependable and repeatable results in professional environments.

In summary, this 30-degree three-jet configuration delivers controlled propulsion, uniform wall cleaning, and durable construction for routine pipe maintenance tasks.