Description

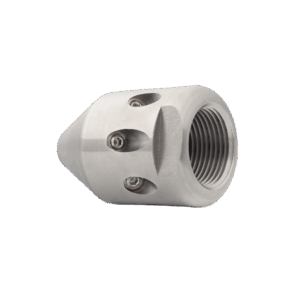

Tarantula 80 Jetting Nozzle – High-Flow Root Cutting Solution

The Tarantula 80 jetting nozzle is engineered for high-flow, heavy-duty pipe cleaning and aggressive root removal. Designed for demanding sewer maintenance applications, it combines strong hydraulic propulsion with controlled rotation to eliminate large roots, grease buildup, and compacted debris in medium to large diameter pipelines.

Tarantula 80 jetting nozzle – Stainless Steel Construction

Manufactured from durable stainless steel, this jetting nozzle ensures corrosion resistance and structural strength under high-pressure conditions. It features a 1/2″ threaded connection compatible with standard high-pressure hose systems. The design supports effective cleaning in pipes ranging from 4″ to 12″.

Dual Rear M8 Jets with Controlled Rotation

The head incorporates two rear M8 jets engineered to produce slow, controlled rotation. Operating from 21 GPM, the hydraulic force delivers strong propulsion while maintaining cutting stability. As a result, large root masses are fragmented and removed efficiently without excessive vibration.

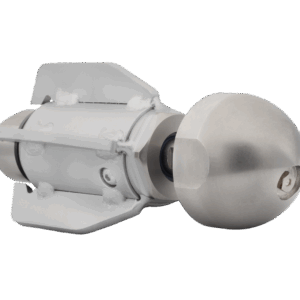

Applications in Heavy Sewer Maintenance

This high-flow configuration is ideal for municipal sanitation systems, industrial drainage networks, and infrastructure maintenance programs. It performs especially well in removing dense roots, hardened grease, and solid obstructions in larger pipe diameters. Consequently, it improves flow capacity and reduces the likelihood of recurring blockages.

Lubrication System for Extended Service Life

The integrated lubrication regulation system reduces internal wear and extends operational lifespan. Because of this feature, maintenance intervals are significantly delayed, making it suitable for continuous professional use in demanding environments.

Tarantula 80 Jetting Nozzle Hydraulic Performance

The hydraulic configuration of this model ensures balanced water distribution across both rear M8 jets. This stability improves tracking inside the pipe and reduces unnecessary vibration during operation. In addition, the controlled rotation mechanism maintains cutting precision even under high-flow conditions. These characteristics make the unit particularly reliable in long-distance cleaning runs and large-diameter sewer systems.

In summary, this high-flow rotating configuration combines stainless steel durability, dual M8 propulsion jets, and controlled rotation to deliver powerful and reliable root removal in 4″ to 12″ pipelines.