Description

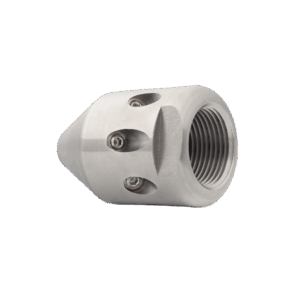

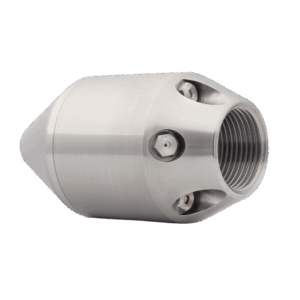

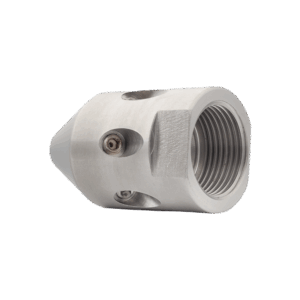

Mini Vibrating 1/4″ jetting nozzle – Descaling and Cleaning Solution for Small Pipes

The Mini Vibrating 1/4″ jetting nozzle is built for tough descaling jobs in small-diameter lines. It combines vibration and hydraulic force to break cement splashes, calcium scale, and compacted mineral deposits. At the same time, it keeps a compact footprint, so operators can work confidently in tight bends, short connections, and restricted access points.

Compact Vibrating Descaling Nozzle for 2″ to 6″ Lines

This model targets pipes from 2″ to 6″. Because it stays compact and stable, it moves smoothly through narrow sections where larger tools struggle. In addition, the vibration-assisted impact helps detach hard buildup that standard rear-jet designs often leave behind.

Stainless Steel Body for Corrosion Resistance

We manufacture the body in stainless steel to handle abrasive environments and repeated high-pressure use. As a result, it resists corrosion and maintains consistent performance over time. For reference, you can read more about the general concept of a nozzle.

Mini Vibrating 1/4″ Jetting Nozzle – Vibration-Assisted Descaling Performance

The rotary head and rear jets generate propulsion and continuous wall contact. Therefore, the tool “taps” and loosens stubborn deposits instead of only flushing them. This mechanical action improves descaling speed and helps restore flow faster, especially when the line has hardened calcium layers or cement residues.

Ideal Use Cases for Maintenance and Corrective Cleaning

Use this configuration for preventive programs and also for corrective work. It performs well in small service connections, interior building drains, and short municipal laterals. Moreover, it supports jobs where operators need a controlled tool that stays effective without excessive hose drag.

- Thread: 1/4″

- Recommended pipe range: 2″ to 6″

- Purpose: descaling, cement removal, calcium deposit removal

In summary, the Mini Vibrating 1/4″ jetting nozzle delivers focused vibration impact, reliable propulsion, and stainless steel durability for small-pipe descaling. Consequently, operators reduce repeat passes and achieve cleaner walls with better control.