Description

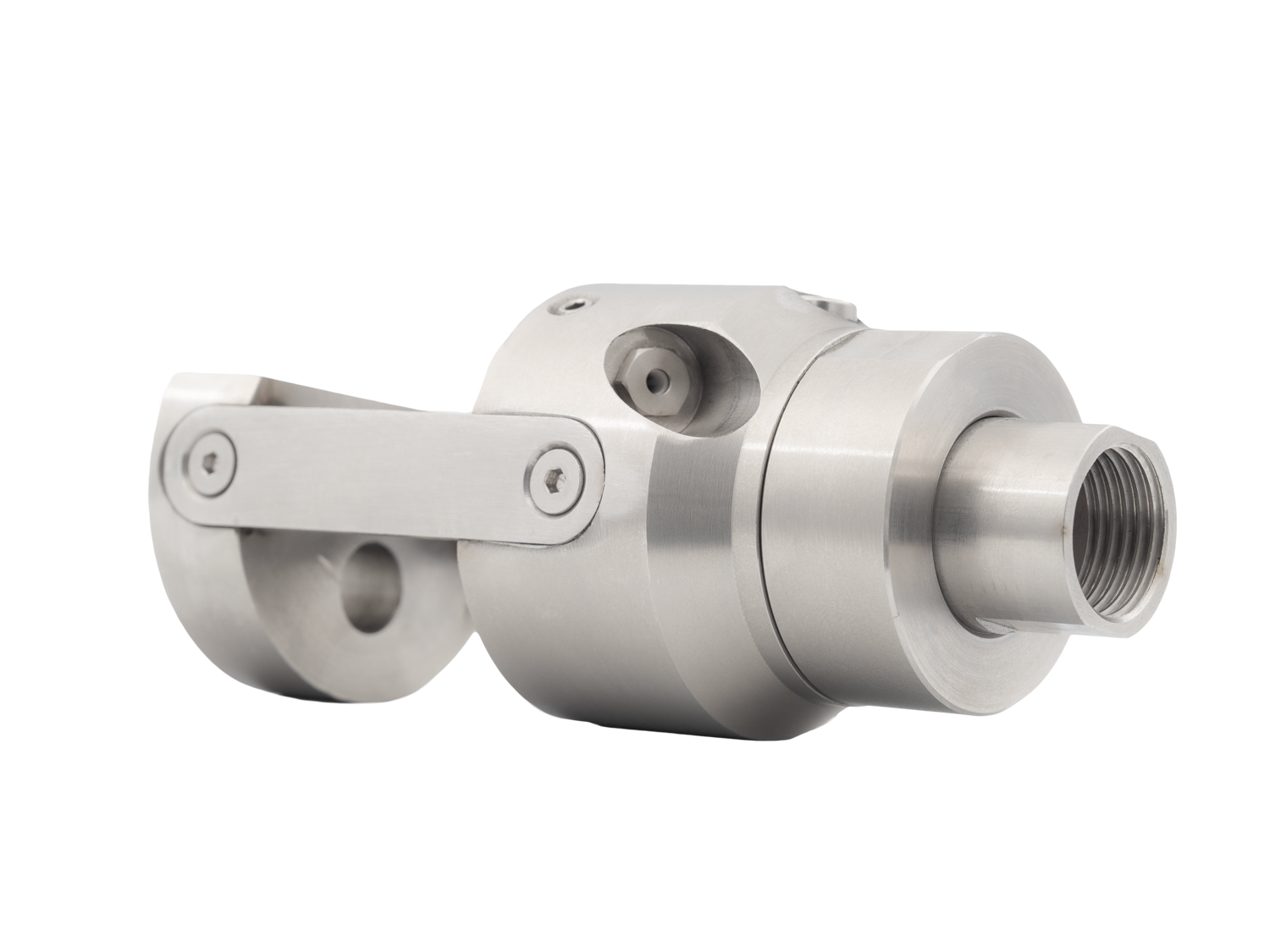

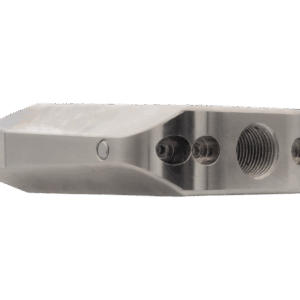

Heavy Vibrating 1/2″ Jetting Nozzle – High-Impact Descaling Solution

The Heavy Vibrating 1/2″ jetting nozzle is engineered for aggressive deposit removal in professional sewer and industrial pipe cleaning applications. It generates strong mechanical vibration combined with hydraulic propulsion to break hardened cement residues, mineral scale, and calcareous buildup attached to pipe walls. This configuration is specifically developed for demanding environments where standard rear-jet nozzles are insufficient.

Heavy Vibrating 1/2" jetting nozzle

Manufactured from durable stainless steel, this jetting nozzle withstands abrasive environments and high-pressure conditions. The integrated 1/2″ threaded connection ensures compatibility with standard high-pressure hose systems. It performs efficiently in pipes ranging from 6″ to 12″, maintaining stability even during extended cleaning operations.

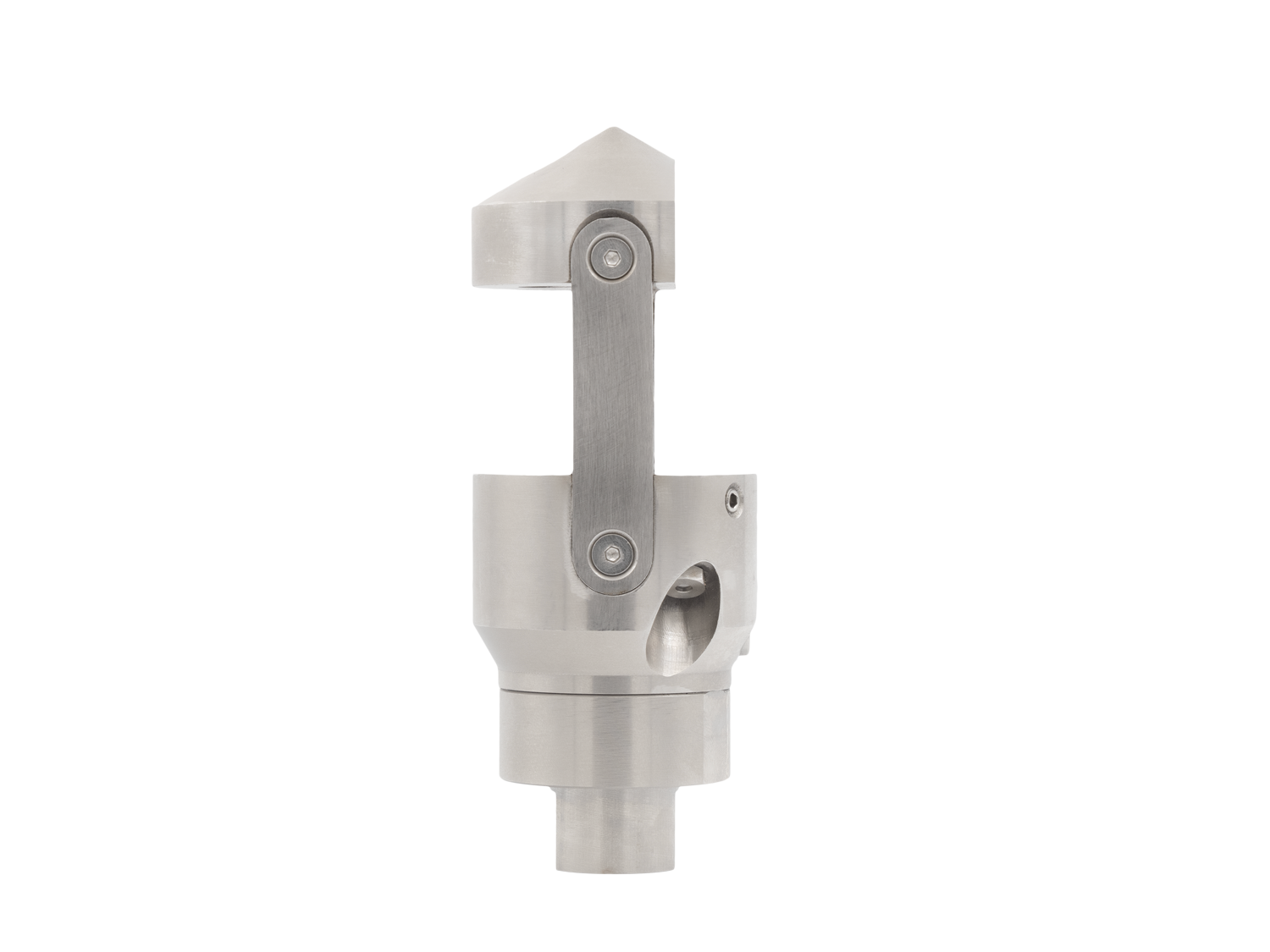

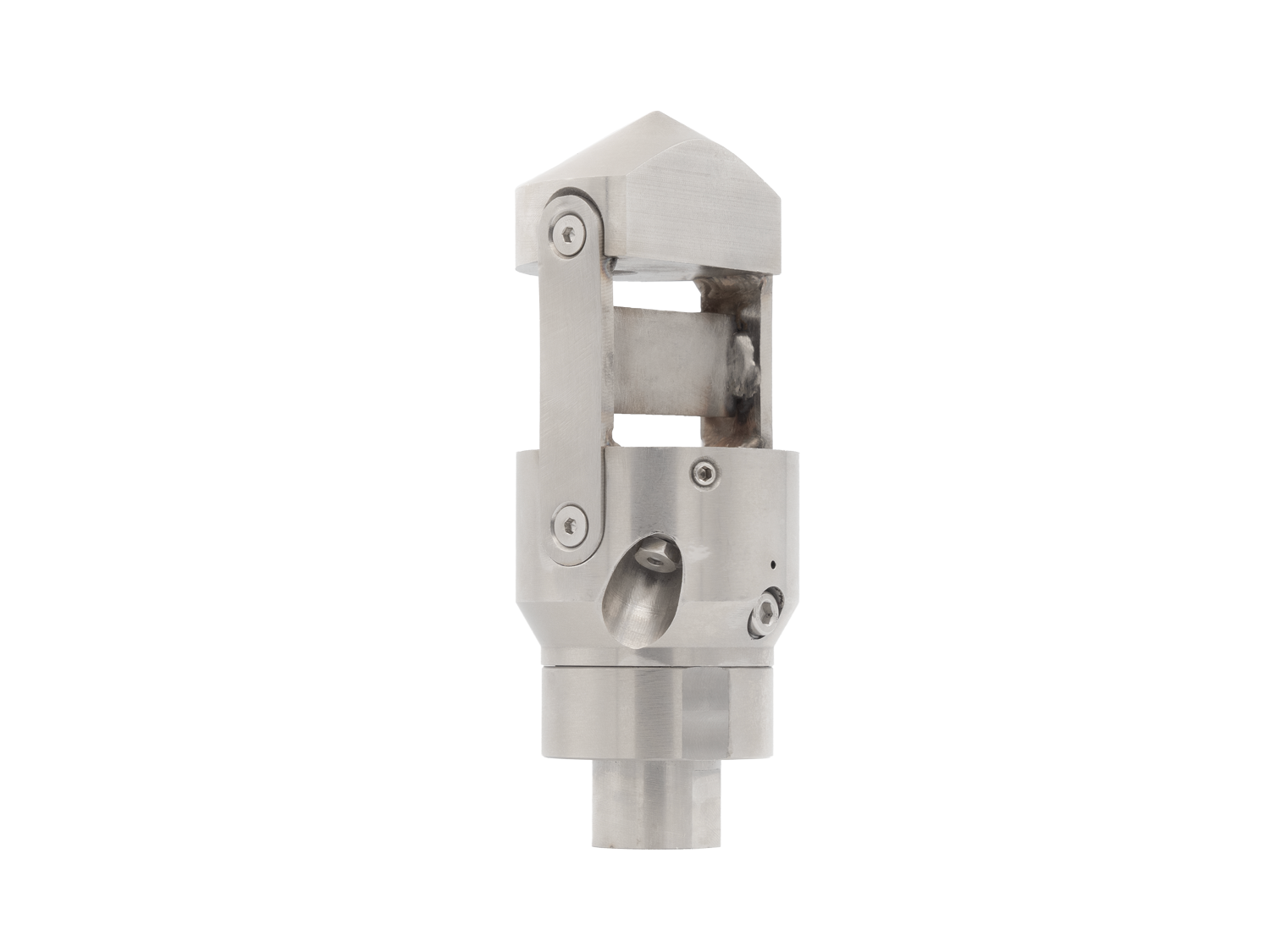

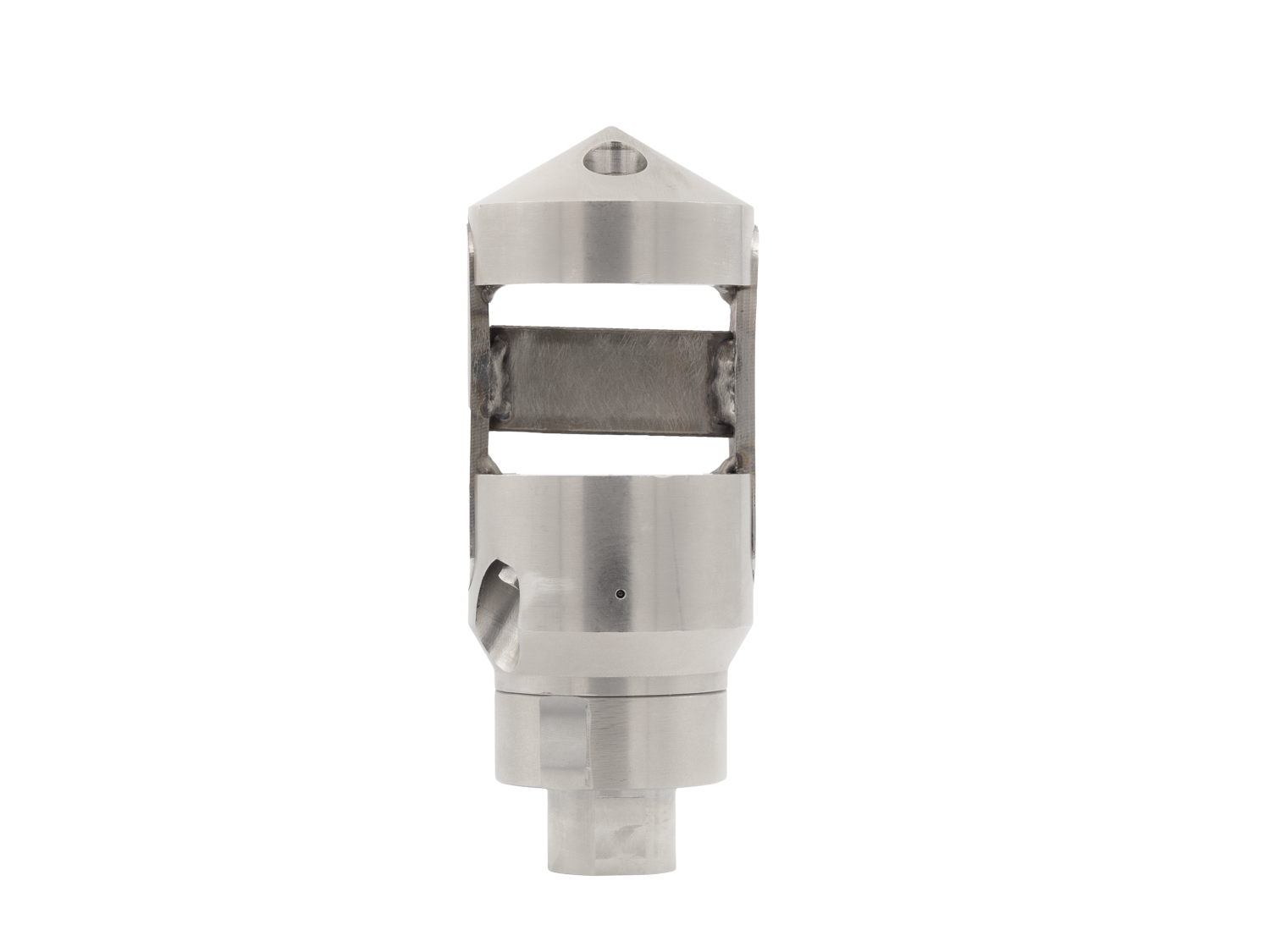

Heavy Vibrating 1/2" jetting nozzle vibration and impact design

The irregular and asymmetrical body design creates repeated rebounds inside the pipeline. As a result, the nozzle continuously impacts hardened buildup. This mechanical action increases surface penetration and accelerates descaling performance compared to conventional hydraulic-only tools.

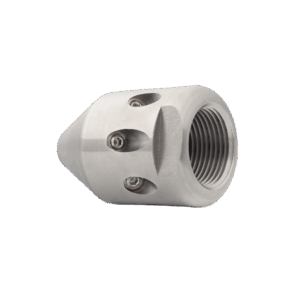

Two Rear M8 Jets for Strong Propulsion

The head incorporates two rear M8 jets positioned to maximize propulsion and vibration force. Operating from 10.5 GPM, the hydraulic layout delivers steady pulling power while maintaining consistent wall contact. Therefore, the nozzle can travel long distances inside the pipe without losing cleaning efficiency.

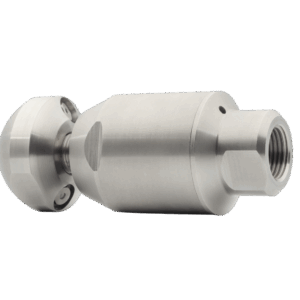

Applications in Cement, Scale, and Root Intrusion Removal

This heavy-duty vibrating configuration is ideal for sanitation systems, construction pipelines, and industrial drainage networks. It performs especially well when removing cement splashes, lime scale, rigid mineral deposits, and compacted root intrusions. Because of its reinforced mass and impact motion, operators achieve deeper cleaning with fewer passes, reducing operational time and improving overall efficiency.

Durability and Long-Term Performance

The stainless steel structure minimizes wear and extends service life under continuous professional use. Its reinforced construction ensures reliable performance in challenging field conditions. For this reason, it remains a dependable solution for preventive maintenance and corrective descaling operations.

In summary, this vibrating stainless steel configuration combines asymmetrical impact motion and dual M8 propulsion jets to provide consistent removal of hardened deposits in medium-diameter pipelines.