Description

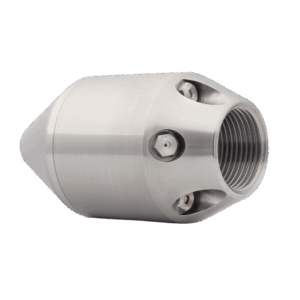

Grenade 70 Jetting Nozzle – Bottom Pipe Cleaning Solution

Bottom cleaning nozzles play an essential role in pipe maintenance when operators need to remove sediment and residue from the lowest point of pipelines. Within this category, the Grenade 70 jetting nozzle delivers reliable bottom cleaning performance through a robust stainless steel body and an efficient rear jet configuration. Therefore, professionals can restore flow capacity during routine and medium-duty cleaning operations.

Technical Features

The Grenade 70 jetting nozzle is manufactured from stainless steel, providing excellent durability and corrosion resistance in demanding sewer environments. Moreover, it features 1” and 3/4” threads, ensuring compatibility with a wide range of professional high-pressure hoses. The nozzle operates effectively in pipes with diameters ranging from 6” to 24”.

Efficiency in Bottom Cleaning Operations

The Grenade 70 removes debris from the pipe bottom using six rear M8 jets angled at 30° and 10°. This dual-angle configuration improves sediment dragging and material transport along the pipe floor. In addition, the nozzle operates with a minimum water flow of 32 GPM, ensuring stable and consistent cleaning performance. As a result, operators achieve deep and uniform cleaning, even in difficult pipe sections.

Applications and Typical Uses

Professionals use the Grenade 70 jetting nozzle in municipal sanitation systems, industrial pipe cleaning, and infrastructure maintenance. These applications often require efficient removal of settled residue and debris. However, the Grenade 70 performs especially well in sewer pipelines where balanced pulling force and bottom coverage are essential.

Durability and Operational Advantages

The stainless steel construction extends service life and reduces wear during continuous professional use. Moreover, the optimized rear jet layout shortens cleaning time and improves operational efficiency. Consequently, operators benefit from reduced maintenance needs, improved pipe protection, and extended pipeline lifespan.

Frequently Asked Questions

What type of cleaning is the Grenade 70 jetting nozzle designed for?

It is designed for bottom cleaning applications involving sediment, residue, and accumulated debris in small to medium sewer pipelines.

What pipe diameters can the Grenade 70 handle?

It operates effectively in pipes with diameters between 6” and 24”.