Description

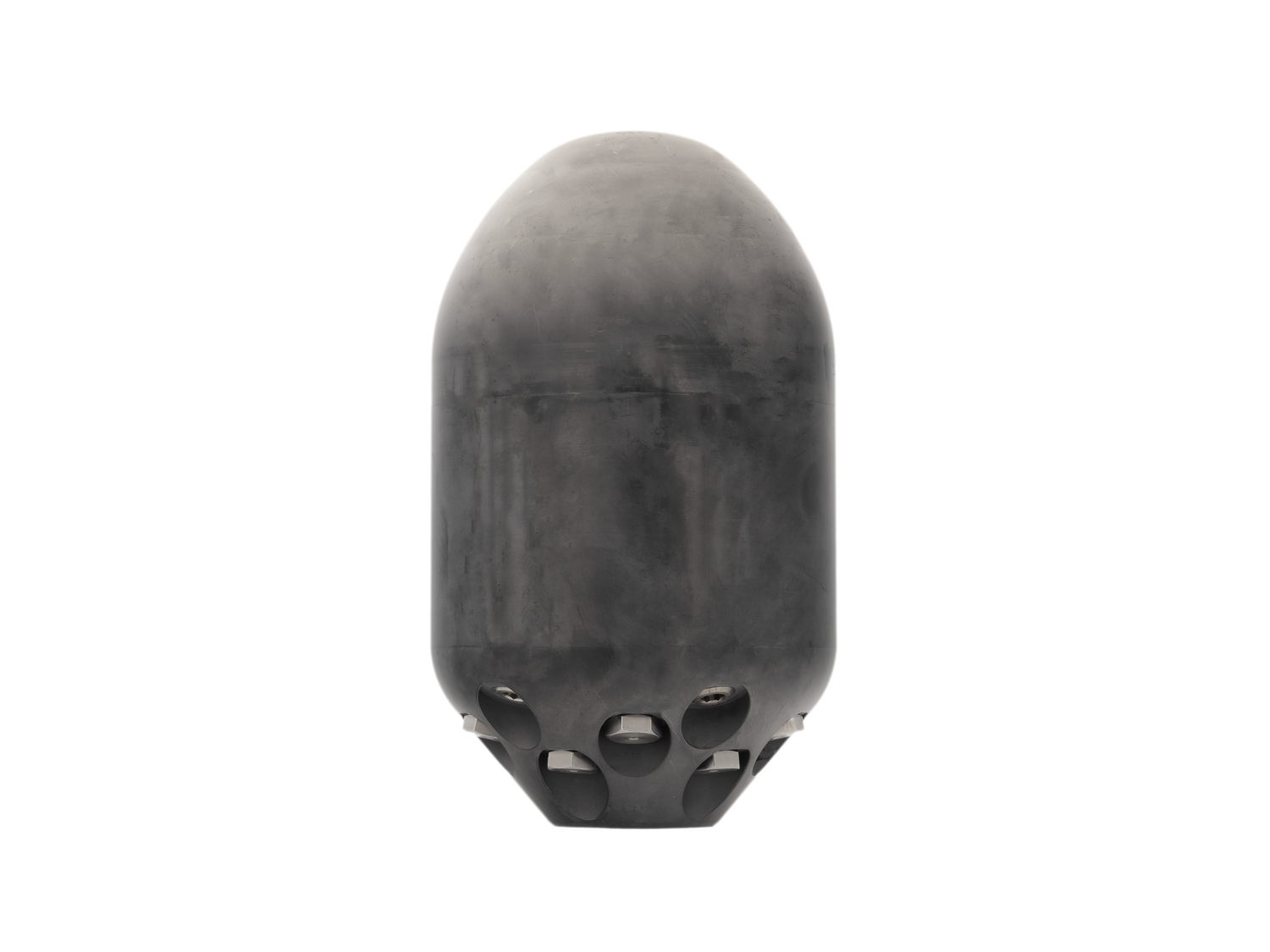

Grenade 120 Jetting Nozzle – Heavy-Duty Bottom Pipe Cleaning Solution

Bottom cleaning nozzles play a crucial role in pipeline maintenance when operators must remove heavy sediment and compacted debris from the pipe floor. Within this category, the Grenade 120 jetting nozzle delivers powerful and controlled bottom cleaning performance. Its robust construction and advanced jet configuration allow professionals to restore flow capacity in large-diameter sewer pipelines. Therefore, it is well suited for demanding cleaning operations.

Technical Features

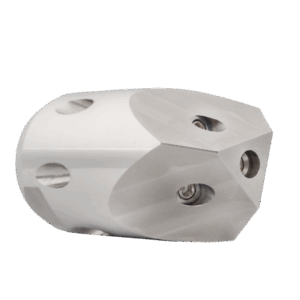

The Grenade 120 jetting nozzle is manufactured from tempered steel, which provides high resistance to wear, corrosion, and mechanical stress. Moreover, it features 1-1/4” and 1” threads, ensuring compatibility with a wide range of professional high-pressure hoses. The nozzle operates efficiently in pipes with diameters ranging from 10” to 48”, covering a broad range of sewer applications.

Efficiency in Bottom Cleaning Operations

The Grenade 120 removes bottom debris using fifteen rear M13-1/4” jets angled at 7°, 15°, and 20°. This multi-angle jet configuration improves sediment dragging and debris transport along the pipe floor. In addition, the jets produce a laminar flow pattern without turbulence, which increases impact efficiency. With a minimum water flow of 53 GPM, the nozzle delivers stable and uniform cleaning performance, even in heavily contaminated pipelines.

Applications and Typical Uses

Professionals use the Grenade 120 jetting nozzle in municipal sanitation systems, industrial pipe cleaning, and infrastructure maintenance projects. These environments often accumulate sand, stones, and compacted residue. However, the Grenade 120 removes this material effectively in sewer pipes between 10” and 48” in diameter. As a result, operators improve flow conditions and reduce the risk of future blockages.

Durability and Operational Advantages

The tempered steel construction extends service life under continuous professional use. Moreover, the optimized jet layout reduces cleaning time while improving debris evacuation efficiency. Consequently, operators benefit from lower maintenance needs, reduced downtime, and improved protection of pipeline infrastructure.

Frequently Asked Questions

What type of debris can the Grenade 120 jetting nozzle remove?

It is designed to remove sand, stones, sediment, and compacted debris from the bottom of large-diameter sewer pipelines.

Is the Grenade 120 suitable for high-flow jetting equipment?

Yes, it is engineered for professional jetting units operating with high water flow and pressure.