Description

Flounder 1″ Jetting Nozzle – Bottom Pipe Cleaning Solution

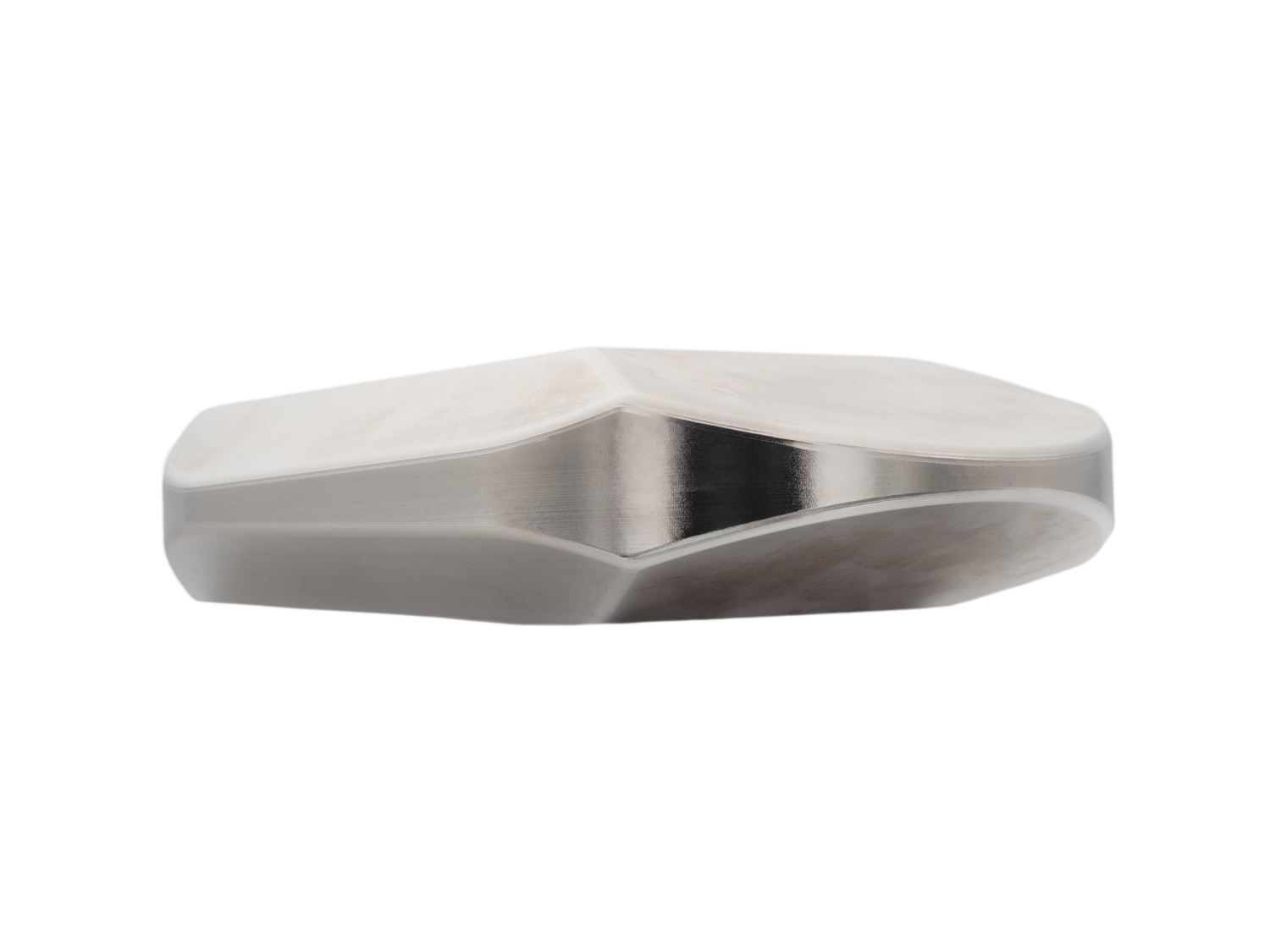

Bottom cleaning nozzles play a key role in pipe maintenance when operators need to remove sediment and heavy debris from the lowest point of pipelines. Within this category, the Flounder 1″ jetting nozzle delivers efficient bottom-level cleaning through its flat profile and optimized jet configuration. Therefore, professional operators can restore full pipe capacity in large-diameter sewer systems with consistent results.

Technical Features of the Flounder 1″ Jetting Nozzle

The Flounder 1″ nozzle uses a stainless steel body that provides high durability and strong corrosion resistance in demanding sewer environments. Moreover, its flat, flounder-shaped design targets bottom cleaning applications directly. The nozzle connects to professional high-pressure hoses and operates effectively in pipes with diameters from 12” to 48”.

Efficiency in Bottom Cleaning Operations

The Flounder 1″ removes bottom sediment through an optimized jet layout. It features eight rear M8 jets angled at 5° and 10°. These jets lift, drag, and evacuate heavy debris along the pipe floor. With a minimum water flow of 53 GPM, the nozzle maintains powerful and stable cleaning performance. As a result, operators achieve reliable results in large-diameter pipelines.

Applications and Typical Uses

Professionals use the Flounder 1″ jetting nozzle in municipal sanitation systems, industrial drainage networks, and large sewer collectors. These environments often accumulate sediment and settled debris. However, the nozzle removes sand, sludge, gravel, and compacted material effectively, even in flat or oversized pipes where standard nozzles perform poorly.

Optional Rotating Fitting and Professional Benefits

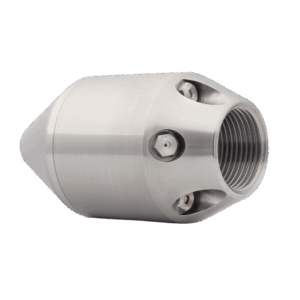

An optional rotating fitting improves operational control. This component allows the hose to rotate independently while the nozzle stays parallel to the pipe bottom. Therefore, cleaning remains uniform throughout the operation. With the fitting installed, the nozzle measures 5.8” x 13.39” and weighs 19.84 lbs, which supports stable handling and accurate positioning in large pipelines.

Durability and Operational Advantages

The stainless steel construction reduces wear and extends service life during continuous professional use. Moreover, the flat body and strong rear pulling force shorten cleaning time and improve efficiency. Consequently, operators reduce downtime, protect pipe integrity, and lower long-term maintenance costs.

Frequently Asked Questions

What type of debris is the Flounder 1″ jetting nozzle designed to remove?

It removes sediment, sand, sludge, gravel, and heavy debris from the bottom of large-diameter pipelines.

Is this nozzle suitable for large municipal sewer systems?

Yes, it is engineered for municipal and industrial sewer systems with high water flow and large pipe diameters.

What is the advantage of the optional rotating fitting?

The rotating fitting keeps the nozzle parallel to the pipe bottom. As a result, it ensures uniform cleaning and prevents uneven surface contact.