Description

Bullet Grenade 60 – Bottom Cleaning Jetting Nozzle

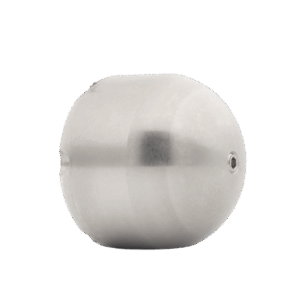

Bottom cleaning nozzles play a critical role in professional pipe maintenance, especially when sediment, sand, and heavy debris accumulate along the bottom of pipelines. In this context, the Bullet Grenade 60 jetting nozzle provides reliable and consistent performance. Its robust construction and focused jet configuration make it an effective solution for restoring full pipe capacity during routine and corrective cleaning operations.

Technical Features of the Bullet Grenade 60 Jetting Nozzle

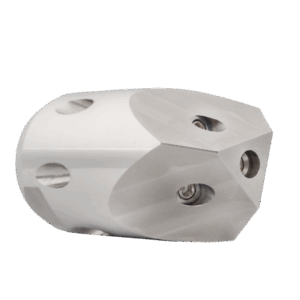

The Bullet Grenade 60 is manufactured from high-grade stainless steel. This material ensures excellent resistance to corrosion and abrasion in high-pressure environments. In addition, the nozzle includes 1” and 3/4” threads. Therefore, it remains compatible with a wide range of professional jetting hoses and cleaning units. The nozzle is designed to operate efficiently in pipes with diameters ranging from 6” to 18”.

Efficiency in Bottom Cleaning Applications

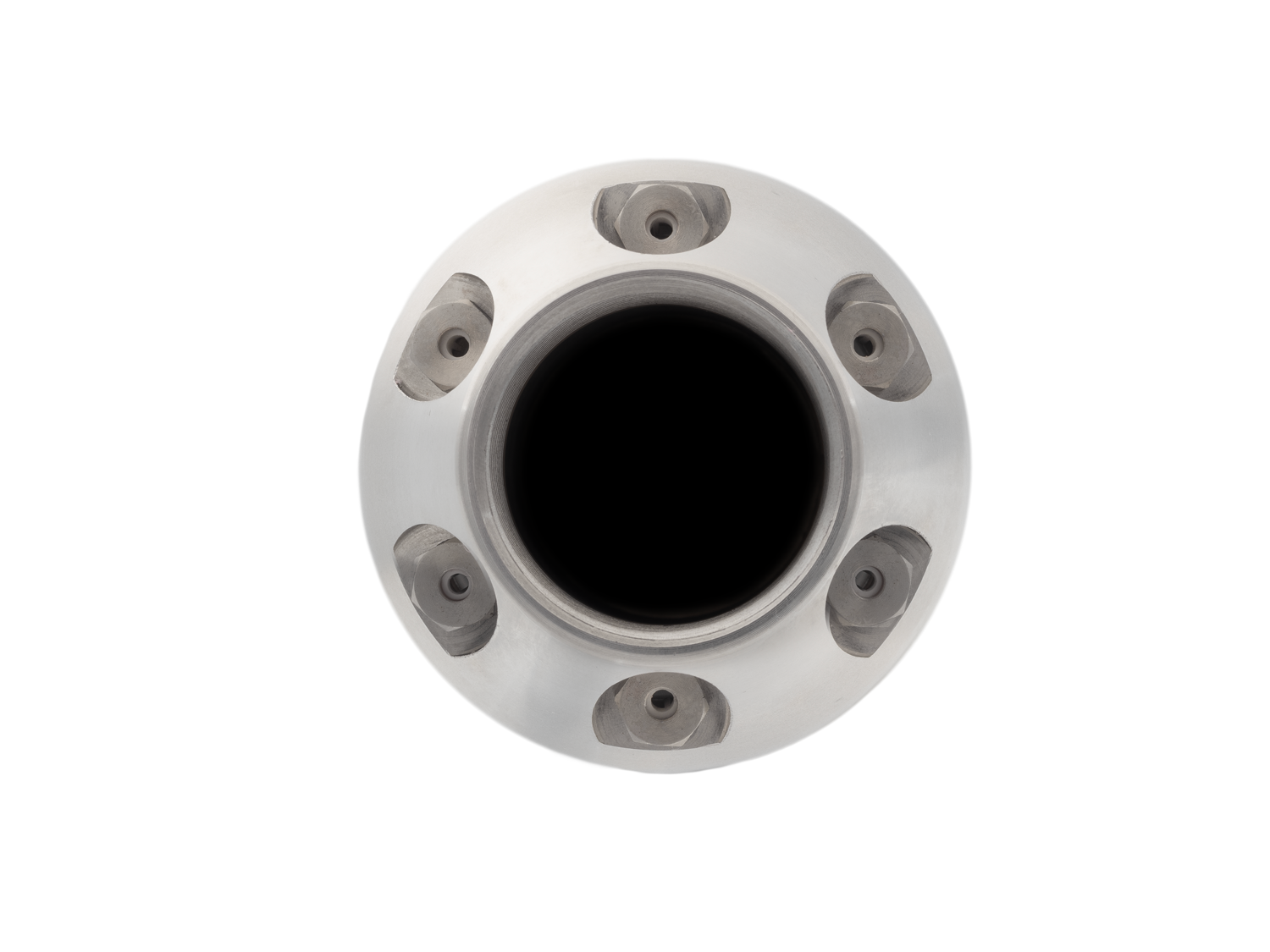

This nozzle is specifically engineered to remove debris from the bottom of pipes. It features six rear M8 jets angled at 30º and 10º. As a result, the jets generate strong backward thrust while maximizing sediment dragging and dirt removal. The Bullet Grenade 60 operates with a minimum water flow of 16 GPM, delivering controlled and consistent cleaning performance during operation.

Applications and Typical Uses

The Bullet Grenade 60 bottom cleaning nozzle is widely used in municipal sewer maintenance, industrial pipeline cleaning, and preventive maintenance programs. It is particularly effective in removing sand, sludge, gravel, and other heavy materials that settle at the bottom of pipes. Moreover, its design allows operators to clean pipelines thoroughly without disturbing the pipe walls.

Design Advantages and Handling

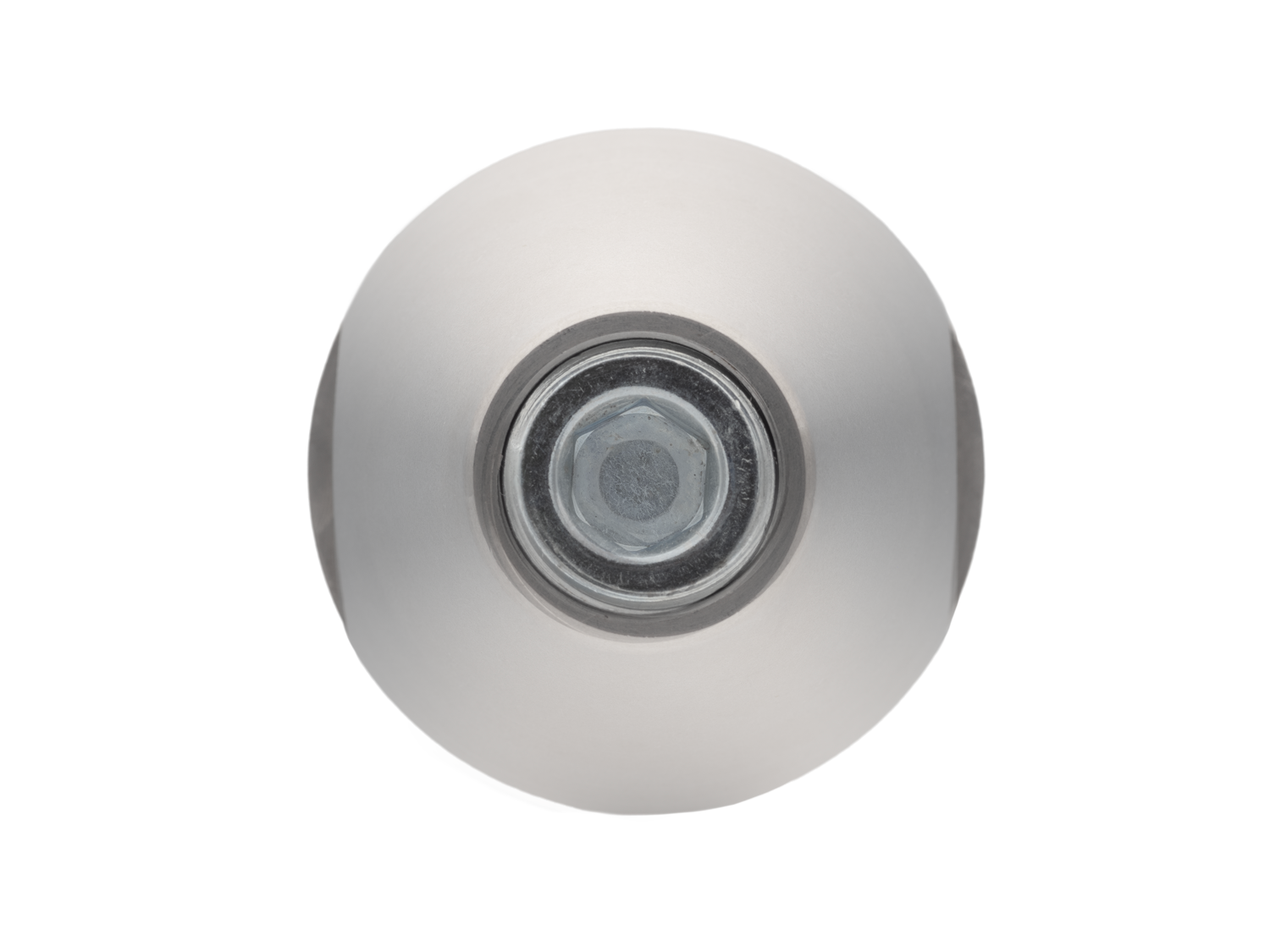

With compact dimensions of 2.3” x 5.2” and a weight of 2.6 lbs, this nozzle offers excellent handling and stability. The absence of front jets simplifies operation when focused bottom dragging is required instead of drilling. Consequently, operators gain better control and improved cleaning precision in sensitive or flat pipeline sections.

Durability and Professional Benefits

The stainless steel construction ensures long service life under demanding conditions. Furthermore, the combination of rear jet angles increases versatility and cleaning efficiency. Regular use helps keep pipes free of sediment buildup. As a result, operators benefit from improved flow conditions and reduced maintenance intervals.

Common Usage Questions

Is this nozzle suitable for preventive maintenance?

Yes, it is ideal for routine bottom cleaning to prevent sediment accumulation and maintain optimal pipe flow.